The machinery manufacturing industry is becoming an integral part of the manufacturing sector, which is undergoing a period of evolution. The conventional methods of machinery manufacturing are often the culprit of reduced efficiency, as they do not allow for efficient methods to manufacture machinery.

The conventional methods do not allow for monitoring the machinery’s health, fully optimizing equipment for machinery manufacturing, multiple failures, and not proper coordination with the human and machinery systems. However, these all evolved with the integration of AI-agentic solutions. The AI agentic solutions just came like the solutions that became the way of manufacturing machinery in a more advanced and enhanced manner.

Agentic AI technologies or solutions dramatically increase the efficiency of machinery manufacturing by facilitating autonomous decision-making, streamlining production procedures, and decreasing downtime. These artificial intelligence (AI) agents evaluate data in real-time, anticipate possible problems, and modify production processes to increase productivity and save resources.

The AI agentic solutions in machinery manufacturing enable real-time data analysis, better production scheduling, optimized resource allocation, adaptive processes, proactive maintenance, reduced unplanned downtime, quality inspection, dynamic and real-time adjustments, etc. These are all benefits, and use cases that are just turning the perception into reality to enhance machinery manufacturing.

Key Statistics

- The agentic AI tools market size has grown exponentially in recent years. It will grow from $6.67 billion in 2024 to $10.41 billion in 2025 at a compound annual growth rate (CAGR) of 56.1%. It will grow to $61.45 billion in 2029 at a compound annual growth rate (CAGR) of 55.9%.

- 29% of organizations say they’re already using agentic artificial intelligence and 44% plan to implement it within the next year to save money, improve customer service, and reduce the need for human intervention.

- According to Eurostat data, in 2024, 10.57% of manufacturing companies in the EU were already using AI solutions – highlighting a growing shift toward intelligent technologies.

- According to Leeway Hertz, fully integrated AI-driven supply chains can reduce operational costs by up to 30% and increase resource utilization by 25–40%.

- According to Salesforce, within 5–7 years, AI agents will take over up to 60% of decision-making processes in manufacturing, and in highly automated factories – even up to 80%.

- 74% of companies that have already implemented AI report measurable efficiency gains (UiPath). 76% believe that agent AI will help reduce operational costs (World Economic Forum).

Understanding AI Agentic Solutions for Boosting Machinery Manufacturing Efficiency

AI agentic solutions in machinery manufacturing refer to AI-powered solutions that can enhance the manufacturing of machinery by increasing productivity through autonomous decision-making and real-time optimization.

These technologies use artificial intelligence (AI) to reduce human intervention and boost overall efficiency by monitoring machinery, anticipating possible problems, optimizing manufacturing, and streamlining supply networks.

In order to enhance robotics and manufacturing automation, agentic AI gives machines the ability to freely adapt, make decisions in real-time, and continuously optimize their performance. This reduces the need for manual control while increasing accuracy, productivity, and efficiency.

Also Read: The Future of Agentic Process Automation

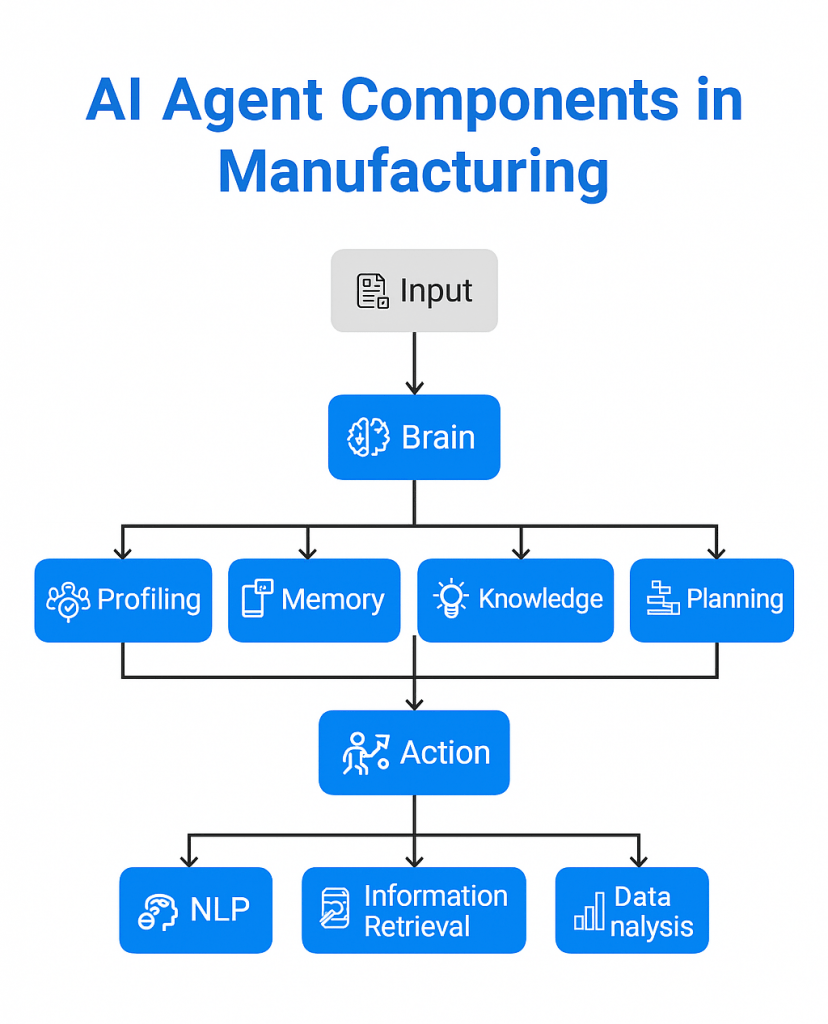

Major Components of AI Agents in Manufacturing

Input

The input component serves as the base of AI agents by collecting and managing an enormous array of variables essential to manufacturing activities.

This data is collected from a plethora of sources, such as machines on the shop floor, sensors embedded in equipment, and human operators using systems.

The inputs collected expressly include operational logs that track machine action, production measures such as cycle times, throughput, and sensor measurements such as temperature, vibration, pressure, etc. They encapsulate a full, real-time view of the operational environment, allowing intelligence agents to monitor process health and assess the conditions to identify anomalies.

In addition, the inputs can be more than just structured data, but also include unstructured inputs, such as text notes from an operator, audio events from a machine’s sound, and images taken from quality inspections.

The range of input types allows AI agents to have holistic visibility that aids in fostering smarter choices and adaptive responses on a constantly changing production floor.

Explore more: The Role of AI Agents in the Future of Warehouse Automation

Brain

An AI agent’s brain consists of a complex integration of cognitive modules that control its level of intelligence and its ability to function and be useful in manufacturing contexts.

- Profiling: This module defines an agent’s identity in the production environment, where its role is defined by goal task or function (ex. is the agent monitoring, optimizing, or controlling?) and organizational goals.

Profiling also involves contextualizing the agent to the appropriate location in the structure of machinery, depending on the relevant workflows and human ingresses.

- Memory: The memory module can learn from prior production data, prior work or interactions, and prior outcomes. It is much more than a database or data retention tool. It allows the AI agent to retain the data not only to recognize patterns and foresee recurring problems, but iterate through customized remediation options based on its experience.

This learning ability is important for the agent to incorporate changes that manufacturing conditions create, and to find efficiency through experience.

- Knowledge: This module is the domain knowledge necessary for intelligent decision-making. This module is made up of the agent’s information related to the production processes, quality measurements, characteristics of tools and equipment, and specifics regarding tooling.

The knowledge module allows the agent to employ best practices, understand compliance, and amend practices due to requirements set forth by products and machinery.

- Planning: The planning module provides the real-time information with respect to demand history and forecasts and stock on hand and forecasts, all of which will allow the planners to generate an optimal production plan. This module accounts for the resource availability, machine capacity and processing constraints which will determine the optimal time of acquisition and where to allocate the resources.

This module makes sure that there are flexible and responsive manufacturing plans, to minimize the idle time and maximize the throughput while balancing cost and quality standards.

Action

The action element of the system implements the goals and strategies defined by the brain into real actions on the factory floor. It automates and coordinates the essence of manufacturing dynamics by breaking down complex processes and assembling them into smaller elements. Each component can be executed either in a serial sequence or simultaneously.

The action module also helps with decision support for human operators, either by providing recommendations or shared tasking for the execution of highly repetitive tasks so that human personnel can be tasked with more significant value work. This level of functionality is facilitated through specialized tools:

- Natural language technologies (NLP) – It enables an AI agent to understand human language and produce and understand text messages, providing a natural way for the operator to communicate with the AI agent. As well, it allows the agent to analyze and extract information and data from textual documents, such as maintenance logs or operator logs.

- Information searching and retrieving technologies – This allows an AI agent to quickly search and obtain relevant documentation, manuals, historical documentation, etc. ,for analysi,s which supports faster solutions and decision making.

- Data analytical tools – These advanced analytical options allow for greater depth of assessment against information provided by the manufacturing data. It can provide trend analysis, failure predictions, and process parameter optimization to continuously improve quality and efficiency.

Collectively, these capabilities provide an intelligent ecosystem for AI agents to create greater productivity, less downtime, and improved operational excellence in manufacturing.

Also Read: How AI Agents Are Improving EHR/EMR Systems in Healthcare

Benefits of AI Agentic Solutions in Boosting Machinery Manufacturing

There are various key benefits of AI agentic solutions in boosting machinery manufacturing. Here are a few mentioned below.

Reduced Downtime

Any carelessness in equipment manufacturing leads to downtime of the system. The conventional system cannot enable those systems that can predict the equipment failure possibilities during the machinery manufacturing that overall results in loss for the businesses.

The AI agentic solutions can predict every possibility and scenario about machinery failures on the basis of machinery manufacturing processes. It overall reduces the chances of downtime for the machinery.

Improved Productivity

During the manufacturing of machinery, multiple problems could be faced but it depends on how we tackle them. The conventional system cannot help too much as it’s not possible to make real-time adjustments with traditional methods, which can disrupt the whole process.

Where the AI agentic solutions are trained on machine learning that has the potential to make real-time changes to prevent the problems that overall increase the productivity of the machinery manufacturing processes.

Lower Operational Costs

Machinery manufacturing involves various uses of energy and resources that charge a lot of costs. Sometimes, due to not having an efficient monitoring system, there could be a high chance of using unnecessary resources and energies that just not only alter the sustainability but also increase expenses.

The AI solutions can implement a system that not only monitors the resources and energy flow but also automatically controls them from overuse, overall establishes sustainability and reduces costs.

Scalable Automation

Automation has been a great benefit of AI agentic solutions. Conventional AI may not be too scalable which could create small issues and delays in machinery manufacturing.

Where the AI agentic solutions have the potential to scale through different production lines and machinery manufacturing processes that overall increase the scalability of the whole processes and system.

Enhances Machinery Quality

You cannot just manufacture machinery and deploy it to make work. This is important to test the quality and reliability of the machinery. The conventional system cannot offer real-time monitoring that generates possibilities to manufacture low-quality machinery.

The AI agentic solutions integration with the IoT provides the facility of a system of real-time defect monitoring that immediately informs the system if any defect is detected. This helps to build the best quality machines that are reliable to take work for a long time.

Top Use Cases Of AI Agentic Solutions In Machinery Manufacturing

There are various use cases of AI agentic solutions in machinery manufacturing as here are a few key use cases mentioned below.

Autonomous Inventory Management

Manufacturing of machinery involves various raw materials and resources that need to be available at the time and also avoid unnecessary availability to reduce unnecessary expenses. The manual management of inventory cannot offer that accuracy.

The AI agentic solutions integration with the inventory enables automation that can track raw material levels across global warehouses in real-time, automatically reorder components using demand forecasts, and optimize Just-In-Time delivery routes that could cut inventory costs by 30%.

Self-Optimizing Production Lines

The machinery manufacturing processes should be dynamic to changes that can adapt to every condition to make the best machinery possible. The AI agentic solutions can analyze the production lines, optimize robotic and human employees’ movements, and reduce the chances of downtime, overall providing the opportunity to develop the best machinery.

The AI agentic solutions enable dynamic rerouting of assembly tasks during machine outages, real-time adjustment of robotic arm trajectories for precision welding, and energy consumption optimization based on utility pricing fluctuation.

Supply Chain Optimization

Supply chain optimization is crucial in machinery manufacturing as it consists of all processes involved in developing the best machinery. There could be various aspects that create the chances of disruptions. The AI agentic solutions can analyze the data to predict disruptions to avoid any potential risk.

The AI agentic solutions enable the prediction of supplier delays using geopolitical and weather data analysis, automatically negotiate contracts with alternate vendors that cannot serve further, and balance production across factories to meet regional demand.

Also Read: The Benefits of Partnering with An AI Automation Agency

Predictive Maintenance And Quality Control

Machinery manufacturing involves various machinery to perform manufacturing processes or operations. Any type of failure and disruption could affect the whole of manufacturing which should be avoided. The AI has been well known for its predictive maintenance capability that can predict failure before too much damage.

A report shows that AI agentic solutions can predict equipment failures 72 hours in advance with 95% accuracy, automatically schedule maintenance during low-production windows, and detect microscopic product defects using computer vision, reducing quality issues by 60%.

Also Read: The Benefits of Partnering with An AI Automation Agency

Challenges while Adapting AI Agentic Solutions for Machinery Manufacturing

There are some challenges while adapting the AI agentic solutions for machinery manufacturing. Here are the key challenges mentioned below.

- Adapting the workplace to the AI agentic in machinery manufacturing is an important challenge. Sometimes the AI agentic solutions and workplace environment cannot match the flow of manufacturing that interrupts the process of machinery development.

- Data fragmentation and quality also affect the manufacturing processes as the data are distributed into various departments and of various quality. This could be a challenging thing to collect all the data and enhance the quality for further processes.

- Lacking mature solutions is a challenge as many manufacturing industries require machinery manufacturing from scratch with limited expertise and resources.

Also Read: Top Benefits of Using AI Agents for Smarter Logistics Aggregation

Final Take

Machinery is the key necessity of various or almost every industry that should be fulfilled in the right way. The machines are also manufactured with various processes and operations that should be performed in the right way. The AI agentic solutions entry in machinery manufacturing has just changed the techniques and ways to an advanced level.

The AI agentic solutions offer better management of resources, enhance efficiency, boost productivity, better manufacturing quality, and much more. Overall, with the evolving and advancing technology, AI agentic solutions are going to take machinery manufacturing to the next level, which could define the future of other industries too.

Looking for? Top AI Development Companies That Help Businesses Scale

FAQs

Best AI Tools for Enhancing Efficiency in Manufacturing Machinery

To improve efficiency in manufacturing machinery, this can be achieved by using AI tools that provide analytics, predict maintenance, and optimize process.

Examples of solutions include machine learning platforms such as TensorFlow and PyTorch, which enable users to develop specialized models for analyzing machinery data. You will also find specialized tools offering industrial grade AI like IBM Watson IoT and Siemens MindSphere. Both of these platforms take in data from sensors in real-time and alerts users to anomalies and to optimize machine performance.

In addition, AI-based robotic process automation (RPA) tools can assist with streamlining repetitive workflows as well as increasing overall efficiency. Choosing the right AI tools will depend on the size of your manufacturing operation, the type and sophistication of data infrastructure, and the exact efficiency you expect to achieve.

How Can AI Agentic Solutions Reduce Downtime in Machinery Manufacturing?

AI agentic applications are able to monitor machinery health and anticipate an impending failure prior to the moment of failure, thus avoiding downtime.

These agents extract value from large data streams from sensors and then look for patterns that would be too difficult for human agents to observe. If awareness is drawn to an anomaly before failure, maintenance teams are then able to inspect the equipment during scheduled downtime, as opposed to an unexpected breakdown, and will greatly reduce unplanned downtime.

AI agents can also adapt and change machinery settings autonomously as needed in realtime, thus limiting any deterioration of the original settings, or optimal changing operating conditions over time.

This predictive and adaptive value allows for greater uptime and increases the performance life of manufacturing devices.

Examples of AI Applications in Boosting Manufacturing Efficiency

AI applications in manufacturing are diverse. Predictive maintenance algorithms can determine when equipment needs maintenance and help avoid costly breakdowns.

Quality control can take advantage of algorithms based on computer vision that can inspect products quicker and more accurately than visual inspection. An example of improving efficiency through the use of AI is optimizing a supply chain through intelligent demand forecasting and reducing any waste in inventory.

AI robotics can layer parts together to create a finished assembly faster and with higher quality and precision than any human operator. AI agents can effectively optimize machine operations through data merged with energy consumption to save on costs, and help preserve the environmental sustainability of your production operations.

Cost Savings from Implementing AI Agentic Solutions in Machinery Manufacturing

The Applications of AI agentic solutions lead to cost reduction through lower downtime, maintenance costs, and greater efficiency.

For example, predictive maintenance can reduce maintenance costs by as much as 25% and reduce unplanned downtime by upwards of 35%. The efficient performance of machines typically uses less energy, resulting in utility savings.

The AI-enabled quality control process reduces error rates, defects, and waste ,leading to reduced material costs and waste disposal costs.

In addition, the automation of laborious and stereotypical work reduces the costs associated with labor while freeing people’s time up to engage in higher-thinking work. Taken together the efficiencies mean enhancements to profitability and an improved return on investment in manufacturing contexts.

I’m Deepika Pandey, an SEO strategist and content writer with 6+ years of experience. I create SEO-friendly content that drives traffic and engages readers. I combine data insights with creativity to help businesses grow their online presence effectively.