Making sure the food industry follows food safety standards is more important now than ever. A seafood processing plant often faces a lot of pressure to keep the supply chain fast and good. The food industry now uses new tools like AI, IoT, and RFID to help with this work. These tech tools help track products, watch food safety closely, and make sure everyone follows global rules. When people in a food company use real-time systems, they can improve their work speed and also follow food safety rules. This also helps them give people what they want, like clear and honest information about their food products and trust that the product quality is good.

Key Highlights

- Real-time quality monitoring has changed the way seafood is handled. It brings together AI, IoT devices, and RFID tags to boost efficiency in every step.

- Food safety, supply chain, and supply chain management all get better with automated cameras and checks. These reduce human mistakes and lower other risks like contamination.

- RFID-based systems make it easier to track the traceability of food products at all times. This helps businesses follow all the right regulatory requirements.

- IoT sensors keep watch on things like temperature, weight, and soak time. This makes sure the product integrity stays strong as it moves through each stage.

- Digital dashboards gather data in one spot. They give quick updates so you can look over the work and catch any problems fast.

The Evolving Need for Real-Time Quality Monitoring in Seafood Processing

Food safety is more important than ever in seafood processing. The supply chain in this industry is very complex. The old ways of working do not give enough accuracy or openness. People and rules need more. Because of this, customers find it hard to trust the food products.

Real-time quality monitoring now helps close these gaps. It uses new tools like AI video checks, IoT sensors, and RFID tags. With these tools, plants can better run their work every day. They also keep track of food products, so nothing goes missing.

This setup helps look after product integrity at each step. It makes sure that people can follow food products from the start, all the way through to the end, in the supply chain.

Challenges in Traditional Shrimp and Seafood Processing

Shrimp and seafood work brings a lot of problems when people keep using old ways. One of the main risks is there not being enough checks for quality. This can let bad things get into the shrimp or other seafood while you handle or keep the product. If you do not look over everything as you work, then freshness and temperature might not be right. This can hurt the shelf life straight away.

Outdated systems can make it hard to keep product integrity. When you watch over products by hand, mistakes can happen. Some stock may go past its use date. Sometimes, this messes up batch controls too. These mix-ups hurt consumer trust a lot. It also makes it hard for people to sell their products in other countries. When you have to depend on people to check things, work gets slower. It can also cost more money than it should.

Another problem in the supply chain is knowing where the product goes at all times. People often call this traceability. Old ways of doing this, like using barcodes, do not let you see every part of the process from start to end. Sometimes, there are mistakes in labels and tracking, and this can stop a business from going forward. All these things show that there is a need for smarter options. When you use ideas that are based on new technology, they can fix these problems. This can make the supply chain flow better and faster.

Rising Compliance Demands in the U.S. Export Market

The U.S. export market is known for having very strict rules about regulatory compliance. In seafood processing plants, these rules are all about food safety and drug administration. The rules are strong because the food safety standards are high. For example, the FDA has set HACCP rules that every plant must follow. These help make sure the food is safe for everyone.

Getting ready to export is not only about meeting safety goals. You also need to keep items at the right temperature and put the right labels on them. If you do not do these important things, you could face big fines. You could also be banned from the market. This can take away money from the business.

Keeping food safe on a large level now needs advanced technologies. The old ways of checking quality do not give all the details for doing what the rules say. But with the use of AI, IoT, and monitoring air quality, companies can follow food safety standards, check quality with less work, and act fast if they have to recall something. These advanced technologies help to meet today’s export needs and make sure there is good food safety and regulatory compliance.

How AI, IoT, and RFID Work Together in Quality Monitoring

The use of artificial intelligence, IoT devices, and RFID readers can really help check the quality of seafood in plants. With artificial intelligence, every part of the work and cleanliness is watched at all times in real-time. This makes sure that rules are always followed.

IoT devices are used in the supply chain to watch things like temperature fluctuations and to help keep the right weight of seafood products. At the same time, RFID tags are used for lot-level tracking. These tags help collect all the data in one place as products move from one point to another. When you use RFID tags and IoT devices together, seafood plants can see and track how each batch moves. This helps keep up with food safety and food safety standards through all the steps of production and export.

Integrating AI Surveillance for Activity and Hygiene Monitoring

Artificial intelligence is used in the seafood industry to help follow food safety standards. Machine learning goes through the data in real time. It can find trouble spots or possible mistakes in food safety or how the food is handled. This helps people fix problems quickly and keeps the seafood safe to eat.

The system uses data mining to watch over workers. This helps lower the risks from germs and mistakes. AI tools also use video to find dirty actions. This makes sure everyone follows food safety rules. If someone does not use clean habits, the plant gets a fast alert. This way, the problem can be fixed at once.

AI also helps keep track of where the food goes. It looks at what people do in the plant, so bosses can see what areas need help. When the managers use artificial intelligence, they turn seafood plants into smart places. These places watch daily jobs closely. This helps keep food safety strong. It also lets everyone see how people work. In the end, it helps keep the rules in place for good results.

IoT Sensors for Temperature, Weight, and Soak-Time Control

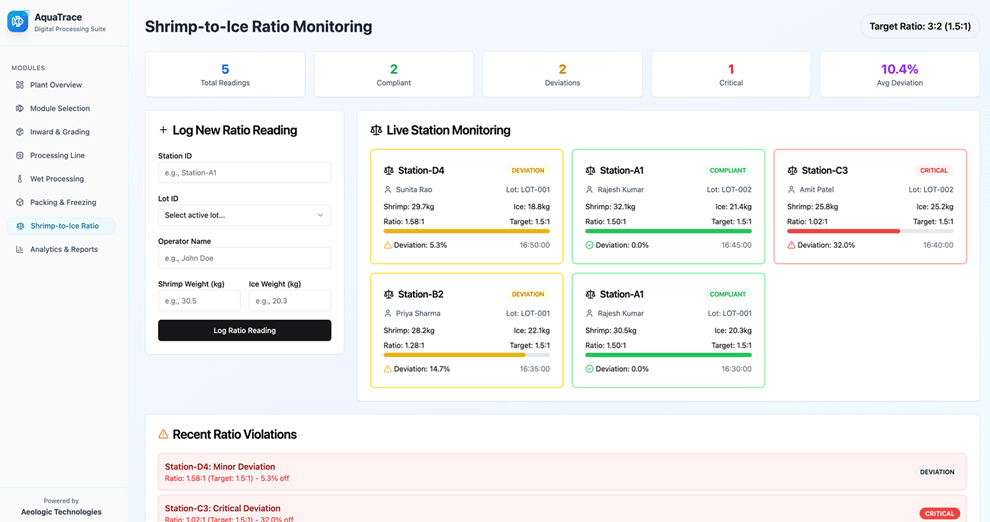

IoT devices are making a big difference in the way people do environmental monitoring in seafood processing plants. These devices help you watch over things like temperature, weight, and how long something is soaking. This is very important to keep product quality high, especially for goods that will be sent to export markets.

In cold chain logistics, there can be many problems from temperature fluctuations. IoT sensors be there to watch the temperature all the time to stop spoilage. If there is any change, the sensors give alarms right away. People can then do something fast. Soak-time sensors also check that seafood sits in marinade for just the right amount of time. This helps to keep the nutritional value of the seafood.

IoT systems can track the weight of seafood. They take away the problems that come from checking the weight by hand. You get the weight numbers fast, and it happens automatically. These sensors talk to each other and work together in a smart way. The systems help people do the work better and faster. They also make things safer by lowering risks when people work with seafood.

RFID for Lot-Level Traceability and End-to-End Transparency

RFID tags are very important in the supply chain. They help with supply chain traceability for seafood processing. You can use the tags to keep track of each food product from when it is made to when it is sent out. The tags hold details like the batch ID, the carbon dioxide level, and when the food expires. This makes it easy to know all about the food products at any time.

When you use real-time scanning with RFID, you can get better control over food items in the supply chain. This gives you more transparency in how things work. The built-in RFID technology helps people spot problems quickly and fix them right away. It helps things move faster and makes sure companies follow global rules. From growing seafood to putting it on the table, RFID lets companies keep a close eye on every part of their supply chain. Food products can be tracked through every step, so people feel more trust in the process and see more value in the final product.

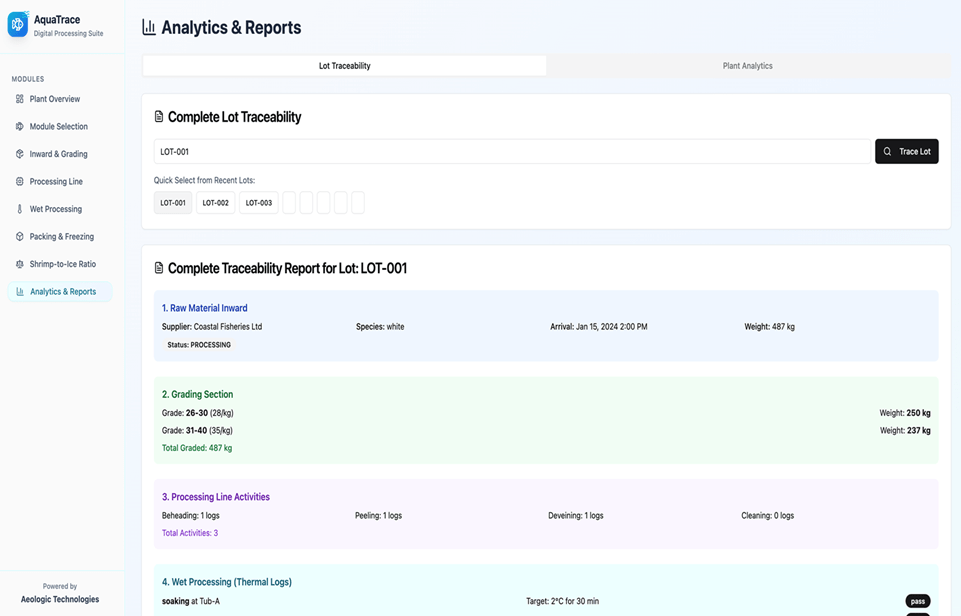

Batch Identification and Backtracking Capabilities

Batch identification is an important part of inventory management in seafood processing plants. These places use RFID tags to watch each batch as it moves. The system helps keep track of things like when a product will go bad and where the ingredients are from.

These plants also use technology that helps them find any batch fast if there is a recall. The tools work in real time, so they can act right away. This cuts down the time they need to respond. It also helps to make things safer and keeps them from losing work or making bad products.

Using rfid tags can help make checking stock much easier. The system can follow all the batches, so you can keep up with the rules. This can help you cut down on mistakes and always know what you have in stock.

Enhancing Food Safety and Recall Management with RFID

RFID technology is very helpful for handling food recalls. When products in the supply chain have RFID chips, food processors can get important details about each item. This helps them know more about the safety and quality of the food as it goes from the maker to the store.

If there is a risk of contamination, RFID can help right away. The system can point to which batches of food are not safe. So, the risk can be dealt with fast and people stay safe. This quick action makes the work better and helps build trust with the public in the way things are done.

RFID has a large role in the supply chain for food safety and product quality. It can read temperatures by itself. This helps make sure food is stored right at all times. Everyone in the supply chain knows the food is safe and good quality because they can see where every product goes. This helps people and businesses feel more sure about their products each day.

Centralized Oversight: Dashboards and Digital Interfaces

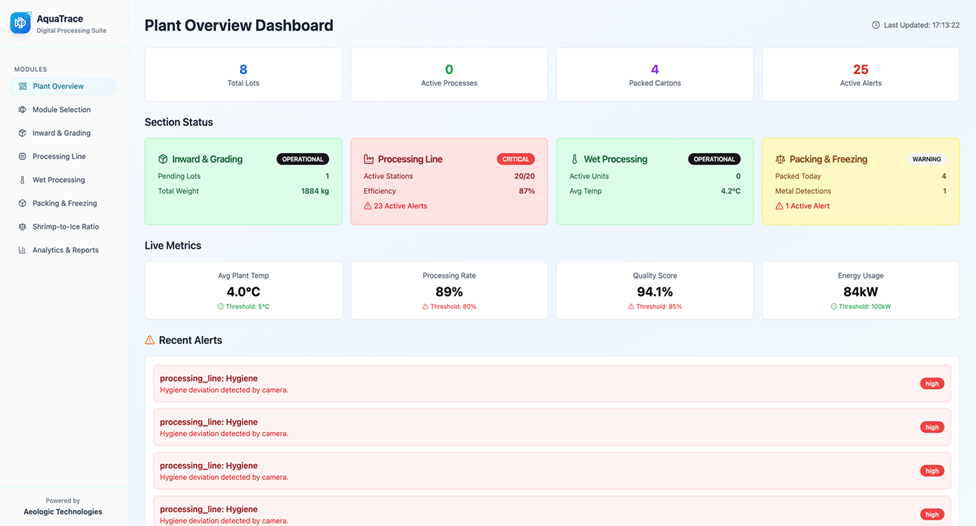

Centralized dashboard systems offer a better way for people to manage seafood processing places. These data analytics tools bring in important numbers from things like RFID tags, IoT devices, and AI cameras.

Managers get updates right away on how things are running and about food safety. They see all this on simple screens. This means there is no need for slow, manual work. Dashboards show easy-to-read reports and send automatic alerts. This helps keep everything open and makes sure the team follows all export rules.

Mobile and Web Inputs for Operators

Mobile and web interfaces help seafood processing plants work in more ways. They let workers put in information themselves. With digital platforms, workers can log data at that moment. This makes it easy to get important things, like temperature and soak time.

These interfaces help people who work at the plant do their jobs better. They keep everything running together in real time. They also help cut down on mistakes because the data is checked as you put it in. The way you enter data is simple, so field teams can share what they see with the main office with ease.

With this digital way, the company can get cost savings. You do not have to use as much manual paperwork. The tasks that get done two times are now taken out.

Real-Time Plant Performance Visualization for Managers

Managers get useful information about how the plant is running with real-time visualization tools. These dashboards show important data from IoT sensors, rfid tags, and AI surveillance. This gives decision-makers clear, helpful insights they can use right away.

The table below shows the main numbers that are given.

| Metric | Applications |

| Temperature Compliance | Ensures optimal cooling conditions for seafood production |

| Batch Traceability | Tracks origin and lot-level information |

| Workflow Efficiency | Highlights bottlenecks in operational processes |

| Product Quality Alerts | Signals deviations from required specifications |

These visualizations help managers see where there are problems fast. They can fix these issues and keep the seafood facilities working well. This way, the places stay up to good standards.

Application Demo :

Key Use Cases: From Shrimp-to-Ice Ratio to Export Readiness

Several real-world examples show that AI, IoT, and RFID are very helpful in supply chain optimization for seafood processing. For example, there are now automated systems that help get the right amount of shrimp and ice mixed. This is important for food packaging. It also makes cold chain logistics better.

Also, there is a need to check the right temperatures, soaking, and glazing to make sure seafood is ready for export. Doing this helps the products meet all strict export rules. When you use real-time tracking, seafood plants can make the food supply chain more open and easy to follow. This is good for export, helps the food supply be ready for many markets, and makes the food supply company strong. Using these steps supports the supply chain and makes the whole food supply chain better.

Thermal, Soak, and Glaze Compliance Tracking

Meeting regulatory requirements is very important in the seafood processing industry, especially when products have to go to export markets. IoT sensors, with help from AI, can check for any temperature fluctuations in all parts of the production. This will help make sure the right thermal standards are always met.

Soak-time tracking is also an important part of the job. It checks how long the marination takes to keep the food safe and good for you. These systems set the soak times for you. This means there will be fewer mistakes, because people do not have to do this task by hand.

Glaze compliance tracking is important to keep product integrity high. The cold chain management systems use set glaze ratios to help keep seafood safe. These systems check the glaze, and spot any issues fast if there is not the right amount. All these new ways work together to keep things good and safe in every part of the job.

Automated Packing Validation and Cold-Chain Monitoring

Automated systems are making the way packing checks and cold-chain steps work in seafood plants better. With new IoT sensors, the plant can follow all the rules. This means there will be less waste and things will run smoother.

Key benefits include:

- Always watching packing weights and the ice that is used. This helps to keep up good food quality.

- Using smart and power-saving tools to check the temperature. This makes sure the seafood stays fresh when it goes to other places.

- Sending alerts to the team so they can fix packing problems right away.

- Helping to follow cold-chain rules in many different parts of the world.

Putting all of this together can give us better tools for food packaging. It also helps to cut down on energy consumption.

Implementation Insights: Customizing the Demo for Your Plant

Success in seafood processing comes from using solutions that match what the plant needs. These solutions must work for the way the plant is set up. They also need to follow the right rules. Aeologic Technologies gives plans and help that fit each plant for its demo. This way, the changes can be good for all types of production plant setups.

By using tools like AI, IoT, and RFID, plants can make the supply chain work well. This helps food companies get their work done faster and with less trouble. It also helps food companies stay on the right side of import and export rules.

Tailoring Systems to Operational Layouts and Regulatory Needs

Customizing quality monitoring systems starts when you look at how every operation works. Each place is different. The size and setup are not the same for all. So, you need solutions that are good and fit their way of doing things. Make sure the quality monitoring matches how they work day by day.

Regulatory compliance is very important. It shapes how a system is built. Following rules like HACCP and FSMA on time is a key part. This helps when people start using the system. It also helps keep things running smooth, so there are no delays when setting up new parts. These custom setups make it easy to get started and avoid problems later.

It is not only about the main things. Every small part, like how the floor is set up or which machines are used, is chosen to fit the plant’s needs. When you use technology that can grow, the plant can change and get bigger or handle new rules when needed. This helps you stay up to date with all regulatory compliance needs, even when things in the business change.

Steps to Launching a Smart Quality Monitoring Solution

When you want to use smart solutions for seafood processing, there are a few important steps that can help you do your work better and faster:

- Assessment: Find out what the plant needs. This means things like checking the temperature and using RFID tracking.

- System Design: Make a plan that uses advanced technologies. Bring in AI, IoT sensors, and cloud dashboards. These will let you control everything from one spot.

- Installation: Put in the systems so they fit with each workspace in the plant. Make sure the new systems work well with your team and their way of working.

- Training and Support: Show managers and workers the right way to use real-time monitoring programs. Give help so everyone can use these tools well.

By using these advanced technologies, plants lower the amount of money they spend on workers. They make more jobs automatic in the plant. This way, people can see all that is going on at any time.

Conclusion

To sum up, AI, IoT, and RFID are changing how the seafood processing industry checks quality in real-time. These tools help people solve many common problems. Because of them, businesses can make food safer, follow rules, and do their work better each day. Things like tracking activity, temperature control, and lot tracking help you keep up the best quality at work. If you want to see how this system can fit your needs, try out the demo from Aeologic Technologies. Go to our website to get started and make your plant better, improve food safety, and boost operational efficiency.

Frequently Asked Questions

How does AI enhance quality assurance in seafood processing?

AI helps to make food safety better by automating quality checks. Machine learning is good at finding hygiene problems fast. It can also look at data to spot issues, so they get fixed quickly. This helps make product quality better in seafood processing and gives people more good ideas on how things work. It also helps to make sure the rules are followed and builds trust with people.

What kind of IoT sensors are used in shrimp and seafood plants?

IoT sensors watch the air for things like temperature fluctuations and how damp it is. They even note how long things soak. These sensors collect data as things go, so the food supply can be watched all the time. This helps make the supply chain safe. Food can stay at certain standards. You can also see where everything is as it moves from one spot to the next.

Why is RFID preferred over traditional barcodes for traceability?

RFID tags are different from barcodes. You get to scan more than one product at the same time with them. This helps to bring more automation and better accuracy in the supply chain, ultimately reducing labour costs. RFID tags also make supply chain traceability much stronger. You can keep all kinds of data on them, like batch IDs, inventory status, and expiration dates. This is good for product integrity. It makes it easy for people to manage products in the supply chain.

Can the system be adapted for different types of food processing plants?

Yes, these advanced technologies are very helpful for many areas in the food industry. You can use them in seafood, dairy, or meat. The systems can change to fit what you have at your place and meet all the regulatory requirements.

How does this demo help with U.S. export compliance requirements?

Seafood plants now use new tools like RFID tracking and AI cameras for food traceability. These help them follow food safety rules and keep up with food safety standards. With these technologies, the plant can meet all the rules needed for export. They can also meet the HACCP rules, which are strict. This lets them get into the U.S. market without problems.

With a strong foundation in software and a growing expertise in AI, I specialize in building smart, scalable solutions that drive digital transformation