In the last few years, generative A.I. has exploded onto the scene. Revolutionary applications like OpenAI’s ChatGPT, DALL-E, and Google’s Gemini now exist right at our fingertips. Not only do these technologies alter our daily lives, but they also transform industries in wholesale ways. This technology transformation is having a disproportionate impact on manufacturing.

Generative AI is changing the way we make things. These systems aren’t just robots on the floor; they are smart systems that make real-time decisions, design parts, predict failures and reduce downtime.

Artificial intelligence is the centre-piece of the factory of the future. But in the immense toolkit of AI, one particular technology is quickly becoming a game changer: generative AI. In this article, we will explore some of the most popular applications of generative AI in manufacturing. We’ll provide some illustrative examples of world-leading manufacturing firms that have transformed their operations with generative AI.

Let’s take a closer look at the 5 best generative AI software & tools for manufacturing in 2025. Whether you’re a plant manager, operations leader or tech decision maker, this guide will help you understand the tools that are driving productivity, quality and cost savings — no technical degree required.

What is Generative AI?

At conceptual level, generative AI will create concepts and optimised designs for use in product design and prototyping, shortening product development time and reducing costs.

Generative AI is any AI model that produces new, original ‘content’, knowledge or solutions, derived from patterns in data. Though it’s frequently used to create text or images, in manufacturing, it’s putting in the work to:

- Design parts automatically

- Predict equipment failures

- Optimize workflows

- Emit reports and other documentation

- Virtualize complete production systems

Think of it as an intelligent assistant that helps you make faster, better decisions without coding or technical expertise. In 2025, these systems are integrated across production lines, ERP systems, and even customer service channels.

Why Manufacturing Needs Generative AI Now?

Modern manufacturing faces several challenges:

- Rising operational costs

- Talent shortages

- Supply chain disruptions

- Pressure for faster, more customized production

Generative AI helps solve these problems by learning from historical data, identifying inefficiencies, and creating smart recommendations and designs without human input.

Sponsoring GenerationsGen Z and Gen Alpha will benefit from the establishment of a new generation as employers embrace the fact that generative AI does more than automate tasks — it empowers the workforce. By utilizing individual employee data, it provides focused training and customized work guidance, leading to a better trained and more flexible workforce.

Advanced data analytics is a game-changer across the entire supply chain. By crunching large volumes of data, businesses can forecast fluctuations in demand, find the best stock levels and work out the most efficient delivery routes.

Product Design

Product design in manufacturing is being transformed by AI, this time in the form of generative. What’s more, standalone tools that turn text into Images are enabling designers to close the meeting range between ideas to designs that are ready for production.

It’s the product designer’s or engineer’s task to define specific design objectives given sustainability goals, production costs, product criteria or compliances and manufacturing parameters. Generative AI are producing various designs based on these criteria.

After developing a design, AI recommends adjustments to optimize for facets like recyclability, material selection, and packaging, in order to guarantee the most efficient, sustainable final product.

Equipped with viable virtual prototypes, engineers and designers can test and tweak design recommendations, and choose the most promising to move forward.

Generative AI helps solve these problems by learning from historical data, identifying inefficiencies, and creating smart recommendations and designs without human input.

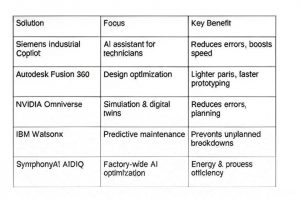

Let’s dive into the top 5 generative AI solutions redefining smart factories in 2025.

1.Siemens Industrial Copilot

What it is: Developed jointly by Siemens and Microsoft, this tool is essentially a real-time AI assistant for floor engineers.In partnership with Microsoft, Siemens launched the Industrial Copilot, a generative AI assistant that helps engineers and machine operators interact more intuitively with complex systems.

AI Assistant for Technicians and Engineers

Key Features:

- Respond to natural language commands (yes sir, you can \”talk\” to it)

- Natural language interface to control machines or access manuals

- Code generation for automation systems

- Anomaly detection based on IoT data

- Real-time answers based on manuals and machine data

- Shows design changes or fixes on the fly

- Communicates to Factory Equipment for Live Monitoring

Use Case: A fab operator can query, “What caused machine X to be down yesterday?” and have an evidence-based answer within seconds.

A European auto manufacturer reduced automation programming time by 40% using Industrial Copilot — speeding up new production line setups significantly.

ROI Tip: Cuts machine downtime by up to 30%, according to Siemens.

Why It Matters in 2025:

In a world where skilled labor is limited, an AI assistant that understands machines in plain English empowers your existing team.

2. Autodesk Fusion 360 with AI Design Automation

Generative Design for Smarter Prototypes and Parts

Autodesk’s Fusion 360 platform now includes AI-powered generative design tools that automatically suggest optimal part geometries based on strength, weight, material, and manufacturing methods.

Key Features:

- Generates multiple design alternatives

- Analyzes stress, thermal, and fatigue performance

- Integrates with CNC and 3D printing workflows

- Reduces material usage and design time

Use Case: A bicycle manufacturer used Fusion 360 to redesign a frame, reducing weight by 25% while maintaining strength — all with AI-generated prototypes.

2025 Impact: Design cycles are shortened dramatically. Teams can move from concept to production in weeks instead of months, with higher precision.

3. NVIDIA Omniverse for Digital Twin Simulations

Real-Time Simulation and Collaboration for Smart Factories

With its Omniverse platform, Nvidia provides manufacturers with the means to build what are known as digital twins: virtual doppelgängers of their factories. Digital worlds like these rely on generative AI to help generate simulations and enhance real-world operations.

Key Features:

- Simulates all production environments on the fly.

- Compatible with Siemens, Autodesk and Unreal Engine

- Uses AI to predict holdups, and simulate layout changes.

- Promotes shared decision making among sites

Case Study: A manufacturer of packaging used the Omniverse to virtually experiment with different line configurations, resulting in an 18% lift in throughput without any physical changes.

Why It’s Crucial in 2025: Simulation saves money and time. Digital twins are now a foundational part of Industry 4.0, which eneable corporations to operate safer, more efficient factories.

4. IBM Watsonx for Predictive Maintenance

Equipment Health Monitoring via AI

The Watsonx platform from IBM fuses generative AI with the power of predictive analytics to avoid downtime. It listens to the equipment (data), and as a result, it makes predictions, recommends maintenance schedules and can even show root cause analysis.

Key Features:

- Enables print history and real-time machine data analysis

- Suggests maintenance actions

- Root cause analysis reports are created

- Compatible with IBM Maximo and other maintenance systems

- Natural language chat to ask about how an asset is doing

Example: A semiconductor facility embedded Watsonx into its maintenance procedures, and in six months experienced a 30% reduction in unplanned downtime. 2025 Value: Unexpected failures can result in hundreds of thousands of dollars in lost production per hour. AI preventive maintenance is a savior, as it deals with solving problems before they can intensify and cause frustration, not to mention cost and lost time.

5. SymphonyAI Industrial Copilot (AIDIQ)

Generative AI for the Smart Factory

SymphonyAI provides AIDIQ — a generative AI copilot for plant operations — designed to address facility specific challenges such as yield improvement, scrap reduction and energy conservation.

Key Features:

- Discussion interface to the factory insights

- Anticipates and avoids quality problems

- Suggests process enhancements

- Compatible with current MES, SCADA, and ERP systems

Use Casee: For example, a U.S.-based food processor started generating over 12% of energy cost savings after implementing a change in equipment scheduling according to AIDIQ recommendations for energy peaks.

What to Look for in AI for Manufacturers If you’re on the market for a plug-and-play AI package made exclusively for manufacturers, AIDIQ offers cold, hard ROI!

Practical Tips for Implementing Generative AI 1. Understand the Problem Before anything else, so that the solution can be built to fit the problem, and not have the problem be the solution, it is important to have an understanding of the problem you intend your model to solve.

- Start Small: Pilot AI in one use case — maintenance or design — before expanding.

- Train Your Team: Offer some basic instruction on how to effectively use AI tools. Integrate

- Data Sources: Combine your ERP, MES and sensor data to derive maximum value.

- Track ROI: Track your results—cost savings, less downtime, faster production.

- Go Gradual: Once you start to see results, implement the use of AI across departments.

Final Thoughts: AI Isn’t the Future — It’s Already Here !

Manufacturers who adopt generative AI in 2025 aren’t just automating — they’re gaining a competitive edge. From smarter designs to self-healing systems, the tools above represent the next evolution of smart factories.

Passionate about breaking down complex tech into simple ideas. Covers everything from AI and software development to gadgets and emerging tech trends.