The manufacturing industry has evolved with various technologies, tools, and solutions and gained a successful height in the last few years. Basically, manufacturing industry manufacturers have a lot of types of products and have a complex supply chain that is surely not an easy task to manage efficiently.

The global market for manufacturing and process control is expected to grow from $86.7 billion in 2020 to $117.7 billion by 2025 with a compound annual growth rate (CAGR) of 6.3% for the period of 2020-2025.

Manufacturing with conventional techniques and solutions is not enough in this advanced and digital world. Many manufacturing organizations have implemented various tools or solutions to establish smart manufacturing that make them stay ahead in this competitive edge.

Brief: Smart Manufacturing with Generative AI Solutions

AI solutions have been one of the potential solutions implemented to manufacture and empower smart manufacturing. In order to increase operational efficiency and decrease downtime in manufacturing, generative AI helps with design processes, optimizes production lines, and forecasts maintenance requirements. As a co-pilot, this technology gives employees unprecedented power.

The global market size for generative AI solutions will be between $34.45 billion and $62.72 billion in 2025. Projects a market size of $62.72 billion in 2025, with a compound annual growth rate (CAGR) of 41.53% from 2025 to 2030. Projects a market size of $34.45 billion in 2025, with a CAGR of 48.6%. The global smart manufacturing market size is calculated at USD 353.23 billion in 2025 and is expected to reach around USD 1,343.32 billion by 2034, expanding at a CAGR of 16% from 2025 to 2034.

We have seen many stats, statements, and detailed descriptions in the introductory part of the article. We will move forward to see some other additional details like benefits and challenges. In the end, we will end the topic with a few concluding words.

Also Read: How Generative AI is Revolutionizing Industries in 2025

What Is Smart Manufacturing?

Smart manufacturing can refer to the optimization of the manufacturing process with the integration of modern technologies to enhance operational efficiency. On the other hand, Gen AI is a type of AI that is trained on various algorithms and has the potential to generate content and analysis of data.

Generative AI provides the manufacturing sector with a powerful tool that can improve quality control, optimize production control, enhance customer service, and greatly increase the overall productivity and efficiency of the manufacturing process by turning raw data into useful goods and services.

Also Read: Top Use Cases of Generative AI in Enhancing Customer Experience

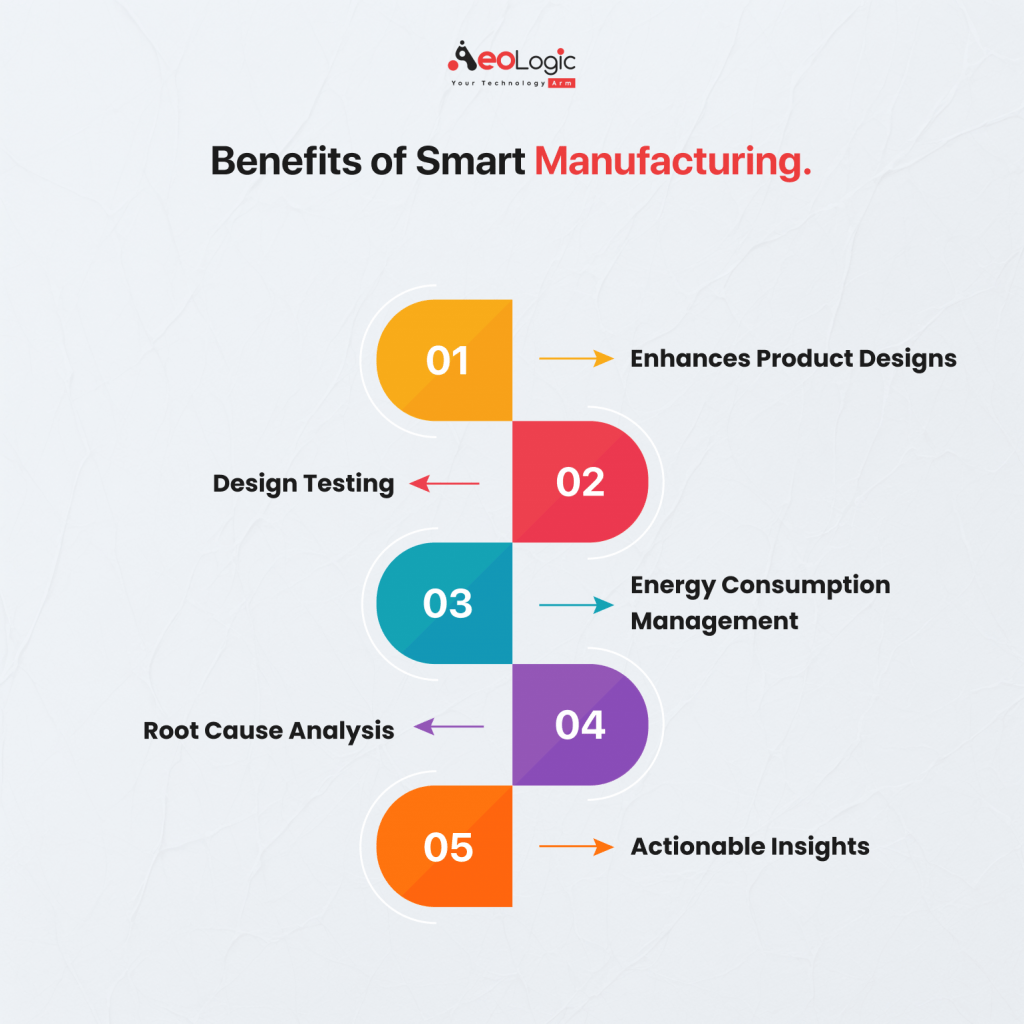

Benefits of Smart Manufacturing with Generative AI Solutions

Generative AI has been one of the greatest technologies developed in recent years, so we must see some benefits in smart manufacturing with generative AI solutions. Below are a few benefits.

Enhances Product Designs

It is very important in the manufacturing industry to have unique and good product designs to make a profit and gain the attention of consumers. The human mind can enhance product design, but it takes a lot of time. Gen AI can generate multiple design alternatives based on product weight, size, color, etc., offering a vast amount of design options that attract customers.

Design Testing

Product testing is another important aspect that should be done with all precautions, standards, and conditions to ensure their reliability. However, with manual testing, it is not possible to test products in less time with high optimization. With Gen AI, testing of products is possible under conditions that help to strengthen the product before deployment to market.

Energy Consumption Management

There are many machineries, processes, operations, etc., within the supply chain that consume a lot of energy. This is very important to manage energy consumption efficiently and reduce the unnecessary usage of energy. With the Gen AI, automation can be achieved for energy consumption that provides energy supply on the basis of needs and also adjusts parameters such as machine speed or temperature.

Root Cause Analysis to Enhance Maintenance

Maintenance of machinery within the time is very important because it reduces the chances of downtime and unnecessary damages, increases cost efficiency, and also enhances the quality of products. Generative AI’s ability to analyze data and predictive maintenance potential helps to detect the issues or faults in the initial stage and reduce unnecessary expenses.

Actionable Insights

Data and insights are very crucial to decision-making in the manufacturing industry, but surely it is not possible with the manual ways of managing operations. Where with the gen AI, data can be extracted from various processes like production lines, customer feedback, market trends, etc., that can be used to make insights. This overall improves the decision-making in less time.

Also Read: The Role of Generative AI in Mobile Application Development

Challenges in Smart Manufacturing with Generative AI Solutions

It’s time to go through some challenges with smart manufacturing with generative AI solutions. Here are a few challenges mentioned below.

- Customization can be a challenge, as there are many specific products that need tailored Gen AI solutions. Customization of Gen AI and deployment can be a complex process.

- Model drift is another challenging aspect as AI models lose their accuracy with the passing of time. This needs regular updates and changes; otherwise, wrong results can be produced.

- The black-box nature of AI can reduce the trust of manufacturers to implement AI, as there is a lack of transparency in the decision-making with AI.

Also Read: Generative AI for Predictive Maintenance in Industrial Operations

Final Words

Generative AI is one of the best models of AI that has the potential to generate content in the form of video, audio, text, graphics, etc. On the other hand, the ability to analyze data also plays an important role in monitoring, decision-making, predictive maintenance, etc.

The manufacturing industry is the industry that needs evolution to manage demand and production, and Gen AI implementation resolves this concern. There are many benefits, like better testing, design options, root cause analysis, actionable insights availability, etc., with Gen AI. But there are a few challenges too, as we have seen in the last paragraph, but they can be overcome with a careful and planned implementation process.

For businesses looking to implement these advanced technologies seamlessly, Aeologic Technologies stands as the best solution. With expertise in innovative AI-driven strategies, Aeologic ensures smooth integration and maximum ROI for your business.

Overall, the manufacturing industry is moving towards evolution with the gen AI, and this is not only beneficial for industry but also beneficial for global development.

FAQs

How is generative AI actually used in smart manufacturing today?

Generative AI is changing how manufacturers design, operate, and optimize their production environments. Today, it is effectively being used in several major ways:

Design & Prototyping: Generative AI can produce and evaluate hundreds of design variances of parts or components with the functional goals and constraints in mind, which can significantly reduce product development cycles.

Predictive Maintenance: By classifying and analyzing robust sensor data and machine log information, generative AI predicts when equipment will likely fail, allowing teams to do maintenance just when needed, reducing downtime, and associated costs.

Quality Control: AI agents can be employed (e.g. using image analysis) to follow the progress of defects in parts or finishes in real-time and detect even microscopic inconsistencies.

Supply Chain Optimization: Generative models can simulate and forecast demand, inventory, and logistics to help manufacturers make agile data-aware decisions.

Human-Machine Collaboration: AI assistants can coach technicians through complex assembly processes or respond to voice prompts to make real-time, machine-based changes within respective systems.

These applications are not hypothetical, but they are being able to be deployed now, by industry leaders across the automotive, electronics, pharmaceuticals and other industries.

What’s the difference between traditional automation and generative AI in factories?

Traditional automation follows explicit, pre-programmed flows—it does exactly what it is told, based on specific conditions. This works well for the routine and repetitive tasks, but not in the face of variability and complexity.

On the other hand, generative AI learns from the data. It can:

- Adapt to a new situational context

- Improve the performance over time

- Generate new solutions, rather than following a script

For instance, the traditional automation may simply stop the machine if a part went out of spec. The generative AI may recognize that the deviation is still within the tolerances for function, provide a suggestion to correct the design, and adapt the process to reduce waste—without stopping production.

This transition from rigid control to adaptive intelligence is what makes generative AI a differentiator in manufacturing.

Can small or mid-sized manufacturers afford to implement generative AI solutions?

The notion that AI is solely for large enterprises is obsolete.

Today’s generative AI tools are getting more modulated and available in the cloud, meaning enterprises don’t need to worry about investing in servers or huge infrastructure. Vendors are increasingly offering:

AI-as-a-Service platforms

Subscription models

Integration with existing MES or ERP systems

Startups, and mid-size manufacturers can always use pilot projects—like AI-driven quality control on one production line—and scale from there based on their ROI.

In fact, depending on the application, generative AI could level the playing field for smaller manufacturers to compete based on agility, customization, and innovation.

What types of data do generative AI systems need in a manufacturing setup?

Generative AI systems learn from a variety of data sources, typically including:

- Machine sensor data: Temperature, pressure, vibration, and speed metrics

- Production logs: Historical records of manufacturing processes and throughput

- Quality inspection data: Pass/fail rates, defect types, resolution metrics

- Supply chain data: Inventory levels, delivery timelines, raw material costs

- CAD/Design files: Used in generative design and simulation

The more structured and clean your data is, the more accurate and useful your AI system will be. Data integration is often one of the first steps in deploying AI successfully.

Is it safe to trust generative AI with critical manufacturing decisions?

Generative AI has remarkable potential—but it must be used with safety, and human oversight.

These systems are safe when:

- Trained on verifiable, domain-specific data

- Tested and used in the real world

- Continuously monitored with both metrics and alerts

The vast majority of manufacturers are using human-in-the-loop models, with AI suggesting actions, and humans making the final decision. As organizations build trust and demonstrate consistent performance, they can automate more of the decision making process.

This isn’t about replacing people; it’s about amplifying human experti

I’m Deepika Pandey, an SEO strategist and content writer with 6+ years of experience. I create SEO-friendly content that drives traffic and engages readers. I combine data insights with creativity to help businesses grow their online presence effectively.