The manufacturing industry has been revolutionized by digital transformation, as it has boosted the smarter efficiency of the whole manufacturing operation. But still, many things are missing that create interruptions and problems to enhance the smarter side of the manufacturing industry.

The problems include a bad quality management system, lack of supply chain visibility, lack of accuracy, not availability of fast and data-driven insights, long customer support system, and lack of integration of modern tools or solutions.

This is all due to still sticking with traditional methods that need to be upgraded as soon as possible. The generative AI in the manufacturing industry has the potential to give a modern and advanced touch to the whole system, which could be a great thing to stay ahead of the competition.

Manufacturing industry can be revolutionized by various benefits with generative AI like better supply chain optimization, automation of routine processes, defect reduction with automatic quality control systems and better customer support. Generative AI solutions are capable of solving the problems that have been created with the traditional system. Generative AI can bring multiple technologies and solutions together to create a smart and advanced ecosystem to enhance the efficiency of the manufacturing industry.

Adoption of Generative AI in Smart Manufacturing Market

The global smart manufacturing market size was anticipated at USD 358.28 billion in 2024 and is projected to grow from USD 392.85 billion in 2025 to approximately USD 900.14 billion by 2034, growth rate CAGR of 9.65% from 2025 to 2034.

The global generative AI in manufacturing market size is expected to be valued at USD 447.32 million in 2024 and is anticipated to reach around USD 13,893.51 million by 2034, expanding at a CAGR of 41% over the forecast period from 2024 to 2034.

A survey indicated that 24% of manufacturers have deployed generative AI at the facility or network level. While moderate, investments in generative AI experiments and proofs of concept are also happening, with 38% of respondents piloting it. Generative AI is expected to boost productivity in the manufacturing industry by over 40% by 2035, according to recent reports from Debut Infotech.

Impact and Benefits In Numbers

- Generative AI can reduce maintenance costs by up to 30% and unplanned downtime by 45%, according to PwC.

- It has the potential to automate tasks that currently consume 60% to 70% of workers’ time.

- Generative AI can lead to productivity increases of 2-3x, 50% better service levels, 99% defect reduction, and 30% lower energy consumption in some cases.

Looking For? Top Generative AI Solutions Provider in India

What is the Role of Generative AI In Manufacturing?

Generative AI in manufacturing refers to the advanced version of conventional AI-powered solutions that can create automated content, advanced data analytics, chatbots, and much more to enhance manufacturing operations in a better manner than ever before. Generative AI enables manufacturers to establish smarter operations with various types of applications and benefits.

The generative AI has been trained on machine learning algorithms and natural language processing that enhance the automation and operational efficiency for the manufacturing industry. Investing in Gen AI technology is worth it in terms of long-term future investment and development.

Explore more: Top 5 Generative AI Tools Transforming Manufacturing

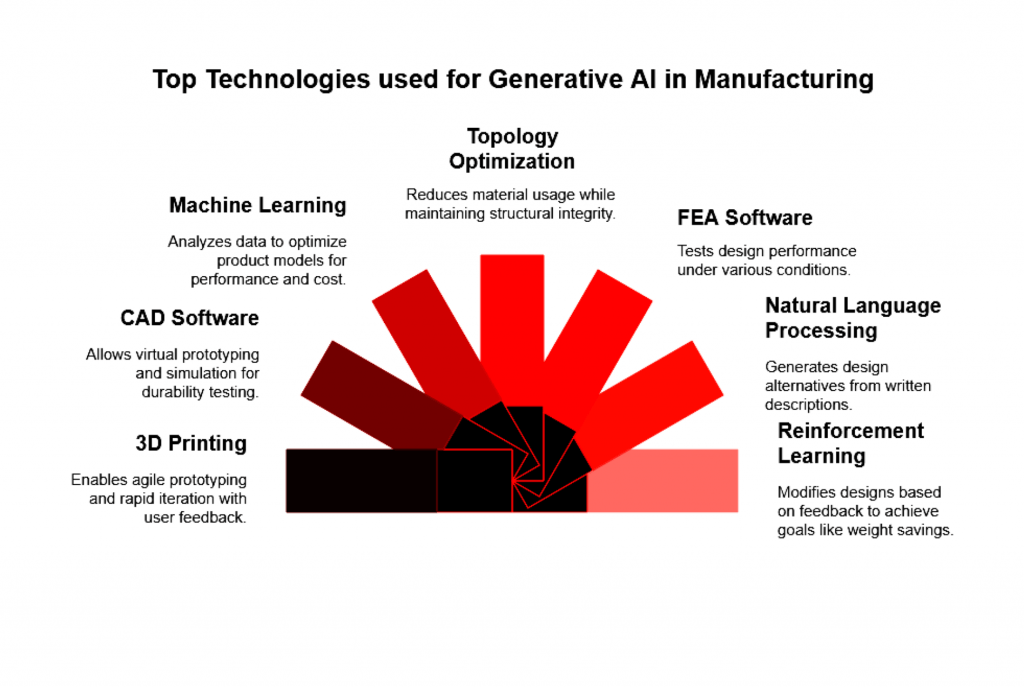

What Technologies Are Involved in Generative AI in Manufacturing?

Generative AI design is a fusion of many technologies used in manufacturing, for example, 3D printing, Computer-Aided Design (CAD) software, and different machine learning algorithms.

These technologies allow you to creatively design and improve manufacturing processes simultaneously to allow for better production outcomes.

Generative AI enables innovation by using a variety of technologies to rapidly form ideas and make production more efficient and effective.

Now let’s look at some of the technologies and methods that are commonly used with generative AI design capabilities in manufacture:

1. 3D Printing

The manufacturing process of 3D printing produces objects layer by layer and is key to agile prototyping and the end product in generative design. 3D printing can iterate quickly and with rapid changes that can be influenced by user feedback, allowing for simplifying production by maintaining quality.

2. Computer-Aided Design

CAD software allows designers to create 3D models of parts and products and enables designers to create, test, and evaluate virtual prototypes and simulations of parts and products to determine the durability, stability, and lifespan of a branded product. CAD software that incorporates AI optimization tools also reduces the iterations and costs of product development, which leads to better project timelines.

3. Machine Learning

Machine learning algorithms are capable of analyzing all types of data, including product specifications and customer feedback, to decide product models that will provide better performance over standard designs or lower cost. It can also facilitate decision making in design for designers, allowing designers to expand their ideas and create better products with higher effectiveness in less time.

4. Topology Optimization

Topology optimization works on the design of materials structures to achieve the intended performance. It allows engineers to eliminate material within the design while not changing the design structural properties. It allows engineers the ability to produce product that is lighter and able to meet performance specifications with less weight.

5. Finite Element Analysis (FEA)

A FEA software program gives engineers and designers the ability to test a design’s performance under various combinations of stress, heat, and vibration. By conducting performance simulation tests, engineers can explore design options to achieve specific operational performance conditions to ensure performance and reliability.

6. Natural Language Processing

Text-based generative design tools enable engineers to develop design alternatives based on a written description, thereby accelerating the design path and quickly toward the designated specification.

These applications read a user description and use algorithms to derive design ideas based on the intended outcome. This allows the design process to be significantly speeded up and yield designs which closely satisfy user requirements and preferences!

7. Reinforcement learning

Reinforcement Learning enables an AI Agent to learn to change or modify a design by rewarding the agent for achieving desired goals such as weight savings (minimizing weight) or strength (maximizing strength).

The AI Agent learns through trial and error, testing different design options and receiving feedback whether or not they meet the desired outcome or objectives. Reinforcement learning is the combination of AI with engineering concepts and principles to improve the engineering design process and produce better results.

Looking for? Agentic AI Agency in India

Benefits of Generative AI in Manufacturing for Smarter Production Efficiency

There are various key benefits of generative AI in transforming manufacturing for smarter production efficiency. Here are a few mentioned below.

Enhanced Product Design And Development

To enhance smarter production efficiency, product design innovation, and development boosts are crucial. The traditional system cannot offer so many options to redesign the product.

The generative AI in manufacturing can conceive, design, and rethink new innovative designs that enable various options for product development. The generative AI not only enhances the option quantity but also establishes a smart and efficient method to do so.

Also Read: Best Generative AI Solutions Providers for Businesses in 2025

Cost Reduction And Resource Optimization

One of the key benefits of generative AI in manufacturing is cost reduction and resource optimization. Sometimes, without proper monitoring solutions, there can be uncontrolled energy consumption for the manufacturing processes. The generative AI can continuously monitor energy consumption and prevent any kind of unnecessary waste of energy. This just doesn’t enhance sustainability and also saves cost reduction.

Quality Control And Defect Detection

Quality enhancement and defect reduction should be done in an efficient manner to enhance the efficiency of the manufacturing processes. The traditional system or conventional AI cannot offer this much facility.

The generative AI algorithm can analyze vast amounts of manufacturing data to detect patterns. This enables immediate detection of defects and enhances the overall product quality. This also enhances customer satisfaction in the manufacturing business.

Supply Chain Optimization in Better and Advanced Manner

Generative AI optimizes the supply chain better than ever before by enhancing various operations. There are various operations like inventory management, logistics optimization, and forecasting that get a boost with this technology.

The generative AI can enable real-time monitoring of inventory to prevent overstock and out-of-stock, route optimization for better logistics, and demand forecasting for predicting future market demands to stay prepared for every situation.

Customization and Personalization

Different types of customers can have different kinds of product choices or types. This is where customization and personalization come into play. Traditional AI cannot offer too much customization and personalization options.

Where the generative AI can understand the customer’s demands through natural language processing and design and develop the product according to that. This helps to regain the customers’ percentage.

Applications of Generative AI in Manufacturing for Smarter Production

There are various applications of generative AI in manufacturing for smarter production. Here are a few key applications mentioned below.

Product Development Process Automation

Automation is the best aspect of generative AI to enhance the smarter efficiency of the manufacturing industry. Generative AI enables product development process automation to automate processes like creation, design, development, and much more, to speed up the overall development process. This enables manufacturers to fulfill market demands to strengthen their position in the market.

Digital Twin Technology

Testing of product quality and various other aspects with traditional systems leads to unnecessary loss. The conventional testing methods involve testing on real products. The integration of generative AI can enable digital twin technology to develop a replica of real-world products. The manufacturers can perform testing operations on the replica to get the exact results and different outcomes with possible scenarios.

Data-Driven Innovation

Since the generative AI has a machine learning algorithm that can be used to analyze large datasets in no time. The traditional system does not have the potential to analyze vast amounts of data, which eliminates the data-driven decision and innovation.

But the gen AI-powered data-driven decision not only enhances the innovation but also enhances the accuracy. This overall enhances the position in the competition as well as enhances the trust of the customers.

Product Planning and Scheduling

Performing various operations like inventory management, forecasting, product planning and others with the traditional system leads to inefficiency.

Generative AI integration can automate these operations as generative AI can analyze the resources and data to create perfect planning and scheduling for the manufacturing processes. This enhances the efficiency as well as the productivity of the manufacturing businesses.

Also Read: How Businesses Can Leverage Generative AI Solutions for Growth

How Much Does It Cost to Implement Generative AI in Manufacturing?

The cost of implementing generative AI in manufacturing varies widely, ranging from $20,000 to over $500,000, depending on the complexity, scale, and specific needs of the project. Costs for integrating AI into existing business applications can range from $10,000 to $100,000. Renting GPUs on platforms like AWS or Google Cloud can range from $10,000 to over $100,000, depending on model size and training duration.

Estimated Cost Ranges for Generative AI Development

The cost of building a Generative AI model depends on the project scope and business requirements. Here’s a breakdown:

Small-Scale AI Solution – $10,000–$50,000

- Suitable for startups and small businesses.

- Typically involves fine-tuning existing generative AI frameworks.

- Limited computational power and moderate data processing needs.

Mid-Sized AI Application – $50,000–$200,000

- Includes Generative AI Integration Services for mobile/web applications.

- It may require training on proprietary datasets.

- Higher infrastructure and cloud computing costs.

Enterprise-Grade AI Model – $200,000–$1 million+

- Custom-built AI models for large-scale automation, decentralized apps (dApps), or enterprise solutions.

- Heavy data processing, high-performance AI tech stack, and security compliance.

- Ongoing AI model retraining and adaptation based on future AI trends.

Also Read: The Future of Advanced Generative AI Solutions for Business

Final Take

The generative AI-powered solutions are a great tool in this digital transformation to enhance the smarter efficiency of the manufacturing processes. Generative AI offers those benefits and applications that are unmatched by the traditional system. Generative AI offers benefits and applications such as predictive maintenance, advanced forecasting, process automation, customer support, better supply chain optimization, and much more.

Overall, generative AI can be the key tool if you want to enhance your manufacturing operations more smartly. This just not only makes you survive in the market but also helps to claim the top spots.

Leverage the power of generative AI to improve efficiency and drive innovation in your manufacturing business and become more competitive. Contact Aeologic Technologies AI specialists now so that we can begin your AI journey!

We Offer: Generative AI Consulting Services

FAQs

How can generative AI be used in the field of manufacturing?

Generative AI in manufacturing involves optimizing product design, automating quality inspection, predicting the maintenance needs of machinery, and streamlining supply chain processes.

Generative AI designs new product prototypes, identifies defects in real time using visual inspection, and simulates production processes to optimize efficiency. AI use cases aim to reduce downtime, decrease time-to-market and support overall company-wide efficiencies.

How do large language models help in design and manufacturing?

We see large language models (LLMs) assisting design and manufacturing teams by reading and interpreting technical documents, developing bulletproof specifications, and helping facilitate departmental communications. LLMs can turn complex engineering criteria into actionable plans, develop reports autonomously, and even recommend optimizations based on pre-existing datasets. They enhanced collaborative workflow between engineers, operators, and management.

How will AI change manufacturing industry?

Artificial Intelligence will reshape the future of manufacturing by creating smart factories in which machines are communicating to one another and autonomously; processes are adapting to real-time changes, and decision-making is becoming data-driven. It will summarily increase automation, improve quality, reduce waste, and reduce cycles of innovation.

Manufacturers will have predictive maintenance, flexible manufacturing lines with no down-time, and manufacturing personalized goods to the highest capacity, which means more efficiency and sustainability overall!

What does AI mean for the future of manufacturing?

AI represents a future where manufacturing is more flexible, cheaper and innovative. Manufacturers will respond faster to customer demand, customize their products more efficiently at scale, and reduce costs and resources.

AI-driven insights lead to continuous improvement, and allow us to leverage technologies such as IoT, robotics, and digital twins that advance the manufacturing capabilities of the factory of the future.

Can generative AI be applied to specific manufacturing processes?

Generative AI can be adapted for application to particular manufacturing processes including additive manufacturing (3D printing), CNC machining, automation of assembly lines, and quality inspections.

For example, in the area of CNC machining, generative AI may generate the best tool path for a CNC machine, or design light yet strong components to be used with 3D printing. It can also assist in automating repetitive tasks and optimizing workflows that are unique to each production environment.

How can generative AI improve manufacturing processes for cost efficiency?

Generative AI increases cost-effectiveness by maximizing resources, eliminating material waste, and reducing equipment downtime via predictive maintenance. It also speeds design iterations, allowing for quicker time-to-market, and reduces labor from automating transactions.

How can Aeologic’s generative AI development services help my manufacturing enterprise?

Aeologic offers personalized generative AI applications that will help you achieve your manufacturing objectives. Their services include AI-driven product design optimization, process automation, quality improvement, and predictive maintenance models.

Also, by utilizing Aeologic’s knowledge, your business can take advantage of new innovations, lower operational costs, and differentiate itself from your competitors with custom AI applications for your unique challenges.

I’m Deepika Pandey, an SEO strategist and content writer with 6+ years of experience. I create SEO-friendly content that drives traffic and engages readers. I combine data insights with creativity to help businesses grow their online presence effectively.