The world of manufacturing is changing fast, and predictive maintenance with artificial intelligence is a big part of this. With AI, companies can find problems in their machines before they become bigger issues. This way, they avoid downtime and save money. It also keeps everything running as it should. With predictive maintenance, people do not wait for machines to break. They fix the issues early so it all goes smoothly. This helps to keep their machines working well, so their work plan is not ruined. In a busy industry, smart ideas like predictive maintenance with artificial intelligence are important. It helps companies get to operational excellence and lets them stay ahead of others.

Key Highlights

- Predictive maintenance uses advanced technologies, like artificial intelligence and machine learning. These tools help people know when equipment could break before it happens.

- By using IoT devices, companies get real-time data collection. This gives them the information they need to see how their machines are doing at any time.

- AI-driven maintenance strategies help keep machines running and lower maintenance costs. This makes the work smoother and lets people do more in less time.

- Big data and data analytics help people find patterns and spot problems. This makes predictive models work better and people can trust them more.

- More U.S. manufacturers now use AI and predictive maintenance. As a result, they have better ways to stop equipment failures and avoid unexpected breakdowns before they start.

Understanding AI Predictive Maintenance in Manufacturing

Predictive maintenance can really help make manufacturing better. It uses machine learning to read both historical data and what sensors are showing now. With predictive maintenance, you get to see problems before they even happen. This way, you can fix things early and keep everything from stopping.

Predictive maintenance is not to wait for problems and fix them after. It is a way for companies to keep learning and get better as time goes by. With data, companies can plan good maintenance strategies. This helps save money. The machines do not stop working as much. It also helps the equipment work well all the time.

What Sets Predictive Maintenance Apart from Traditional Methods

The big difference with predictive maintenance is in how you do the work. With other ways, like reactive maintenance, you do not fix the problem until something is already broken. This makes you and other people wait, and problems can show up without warning. Because of this, maintenance costs can go up. At first, fixing things when they break might seem easy. But later, this way can slow how things get done and also make work less safe.

Preventive maintenance is a way to keep things working well. With this way, you look at and fix machines often. You do this at set times or after the machines have been used for some time. This helps the machines keep running as they should. But, sometimes, you may work on the machines more than you need to. At other times, you can miss a problem if it depends on what the machine is doing right now.

Predictive maintenance lets you take better care of your equipment. It uses data analytics to watch your machines in real time. This helps you know the condition of your equipment at all times. You or your team can get to a problem as soon as it happens. It is like having a health check that stays working all the time for each machine. With predictive maintenance, you can lower your maintenance costs, avoid downtime, and keep things running well for many years.

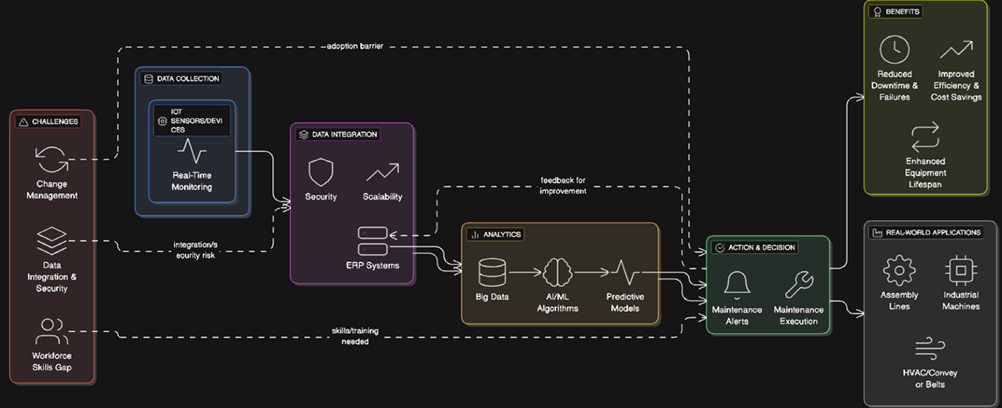

Key Technologies Powering AI Predictive Maintenance

Many new and strong tools make predictive maintenance with AI much easier.

- IoT devices: Sensors are in these machines. They watch things like temperature and vibration all the time. This happens in real time.

- Big data analytics: A lot of data comes in. It is looked over to find good, useful details.

- Artificial Intelligence: AI takes this big amount of data. It looks for trends and patterns in it. This helps know when the machine might break. It can help stop potential failures.

- Data integration systems: ERP systems put all important details together. This helps the team use their data. They can make better choices.

These iot devices, erp systems, big data, real time, artificial intelligence, and data analytics help find and stop potential failures.

When these advanced technologies are used together, they help spot problems early and prevent breakdowns. This helps keep everything working well. The first step is data collection by iot devices. These iot devices also check things in real time. After that, big data and artificial intelligence look for any small changes in the way things be working. This help people fix problems before they get worse. Using big data, artificial intelligence, and real time tools makes the work day better for all. It also help everyone get more done.

Benefits of AI Predictive Maintenance for US Manufacturers

For people in the U.S. who make things, the use of predictive maintenance can help a lot. This type of maintenance management is there to stop unexpected breakdowns. It helps to keep machines running steady and safe. The workers can get more work done, and the company can meet what customers want every time.

There is another good thing about using this way. It brings down maintenance costs as time passes. When teams do not waste time on work that is not needed and pick fixes with data, they save time and resources. This helps raise operational efficiency. With more jobs getting done and better systems in place, companies stay strong. It helps them last and keep going for many years.

Reducing Downtime and Equipment Failures

Predictive maintenance can help lower the chance of unexpected breakdowns. The system keeps an eye on your equipment at all times. It looks out for any early warning signs that a problem could be coming up. This way, you get to fix small things before they turn into big issues. Your machines stay up and running, so your work does not need to stop.

If a machine stops working when you do not think it will, you may lose a lot of time and work. Predictive analytics with AI can help you avoid times like this. When you use this tool, you can know when you need to fix things before they have big problems. So, your work keeps going, and you will not feel stressed about the machine breaking.

Less downtime means your business can make more money. If you find problems early, you can fix them before they turn into something big. This helps you spend less money on repairs and keeps your machines working well. It also helps companies have more control of their equipment and tools.

Improving Operational Efficiency and Cost Savings

Boosting operational efficiency is the main goal of predictive maintenance. The maintenance teams do not only work on a set schedule or wait for something to go wrong. They use real-time data to know what jobs need to be done right now. This helps them not waste time on checks that are not needed. It also helps the machines to run better and for a longer time.

When maintenance costs go down, manufacturers have a chance to save more money. Predictive maintenance helps them use what they have in a smarter way. Teams only do repairs when it is really needed, not only because it is time for it. This lets the equipment stay running for more time. There are fewer delays for repair. There are also fewer times when things break and need an emergency fix.

In the end, manufacturers get to run their work better when they use technology for decisions. AI makes their equipment more dependable. It helps them get more money too by using maintenance strategies from data analytics.

How AI Predictive Maintenance Works: From Data to Action

Predictive maintenance begins when IoT devices are put on the machines. These devices collect data all the time. Some of the things they check are temperature, vibration, and pressure. All this input data gets sent to be checked. This is how data collection helps with predictive maintenance.

With predictive analytics, AI checks the data to find out if something is about to break. It gives advice and lets the maintenance team know if a problem might come up soon. This way, the maintenance team can act right when they need to. It also helps stop big problems, and lets the equipment work well for a longer time.

Role of IoT Sensors and Real-Time Data Collection

IoT sensors are very important for predictive maintenance. They keep checking machines all the time. These sensors watch for changes in heat, pressure, humidity, and vibration. The devices record important details every hour of the day. This helps all systems stay up to date. It also gives people in manufacturing the information they need to know what is happening with their machines.

IoT devices are really important in maintenance work. They watch what is happening all the time. This gives a business the chance to spot problems before they show up. When you get good information from these iot devices, the predictive models work better. With this, workers find out about issues on time. They can stop things from breaking down before the problems get worse.

These sensors help make work easier for everyone. They fit in well with maintenance management platforms. Manufacturers have dashboards that are easy to use. People can check everything from there, see when problems happen, and get updates fast. With internet of things tech, predictive maintenance is not just smart. It can save money and change how people do things in a good way, too.

Machine Learning Algorithms for Predictive Insights

Predictive maintenance is all about using machine learning right in the middle of it. The systems take in a lot of data from the machines. They look for patterns in all that data and see if there is a problem coming. With predictive maintenance and machine learning, you know what is going on with your machines. This helps you take care of any issue before it gets worse.

The data that machine learning uses does more than just show changes. It can look ahead and help people guess when something might not work. This is good for manufacturers. They use these guesses to know the best time to fix their machines. This way, they do not spend money to repair things that do not need fixing yet.

Also, these algorithms get better over time. They use historical data and information from now to learn and make their predictive capabilities stronger. Because of this, they are very useful for people who want to change or improve maintenance strategies in different industries.

Overcoming Challenges in Implementing AI Predictive Maintenance

Using AI predictive maintenance is not easy. Many groups struggle with it because they have to collect large data sets. Most times, their teams do not have enough people who know how to do this work. It also takes a lot of time when they have to connect several systems to one control dashboard. They also must keep everything safe, and that makes things take even longer.

Another hard thing with change is that many people feel some pushback. A lot of people do not want to try new digital ways for maintenance. This is something that happens with many manufacturers. To get over these problems, you need to take clear steps. This helps the move to predictive maintenance be smooth.

Data Integration and Security Considerations

Bringing all the data together in the systems we use now takes planning. You need to get information from ERP tools and from maintenance systems. A lot of the time, they are not in the same place. These have to work together well so there are no problems.

| Integration Factor | Description |

| ERP System | Putting all maintenance data in one place to help teams in different areas work together. |

| Security Protocols | Keeping data safe when moving it and checking for any break-ins. |

| IoT Device Outputs | Lining up real-time data so you get the right information. |

| Scalability | Making sure the system can change for different machines and their needs. |

These steps help you use data in an easy way. They also help get rid of some of the risks that come with having a lot of data or with security problems.

Addressing Workforce Skills Gaps and Change Management

Using AI for predictive maintenance shows that a lot of teams do not have enough practice with digital systems and AI. The people who use these tools often need more training. Every time one new system comes out, companies have to make new training for workers. This helps their teams know how to use the new systems and feel sure about it.

Some workers do not like to stop doing things the old way. They usually use the same steps to avoid problems. So, they may not feel good about trying new tech-based ways. Good change management is needed to help with this. It is helpful to show workers the benefit of these new tools. Letting them try the tools also makes them feel better about using new tech.

Investing money in human resources that work with platform automation helps each part of the business work better together. In this way, the company makes sure that moving to predictive maintenance happens in a smooth way.

Conclusion

AI predictive maintenance is changing the way people work in the manufacturing business. It uses advanced technologies to help your work go smoother and faster. With these tools, machine downtime goes down. This is why more companies now add predictive maintenance with machine learning in their process. This way, they can stay ahead of others in the market and keep their work flowing well.

With IoT sensors and machine learning, you can see how your machines are doing in real time. This lets you act fast, fix problems early, and stop big issues before they come up. When you do this, your costs can also go down. If you want your manufacturing business to get better results with AI predictive maintenance, we are here for you. Talk with the team at Aeologic for a free chat. They will explain how these smart tools can work for your business and help you reach your goals for operational efficiency.

Real-World Applications of AI-Powered Predictive Maintenance

Many manufacturers in the world now use predictive maintenance. It helps them get better results. With this, they can also raise customer satisfaction. They use real-time data to spot problems early. So, there is less wasted time. There are also fewer items that need to go back. This way, the quality gets better for all.

A good example of this is when people use machines on assembly lines. AI can help the machines know the best time for repairs. This helps to keep everything working well at each checkup. When companies use these ways, people trust them more. Customers know the products will be good and can be counted on.

These cases show that companies keep good work standards with AI-powered solutions and predictive maintenance. It helps them get the most out of their machines. With this, they can find problems before they get worse. This can save both time and money for the company. You can see how using AI and predictive maintenance makes things work better and gives good results for everyone.

Frequently Asked Questions

How can Aeologic help manufacturers implement AI predictive maintenance?

Aeologic gives you predictive maintenance answers that meet what manufacturers need. The team brings ERP systems and new technology together. This helps you set up easy and smooth maintenance management at your place. These tested tools show you things so that you can catch issues even before they happen. You can also see cost savings and help your work get better with these solutions.

What types of manufacturing equipment benefit most from AI predictive maintenance?

AI-driven predictive maintenance works well for things like industrial machines, HVAC systems, and conveyor belts. These types of equipment often have potential failures. When you use predictive maintenance for your assets, you can lower maintenance costs. This lets you keep your supply chains moving. It also helps your production go smoothly.

Is AI predictive maintenance suitable for small and medium-sized manufacturers?

Yes, predictive maintenance is good for all makers. It does not matter if your business is big or small. People in this field use ERP software. This ERP software can grow with them as their needs change. It helps to make better maintenance strategies that are not too costly. These strategies stop most slow-downs and other problems. Predictive maintenance also helps with operational efficiency. This is good for small and medium companies. They want to make things work better, but they do not want to spend too much money.

How quickly can manufacturers see ROI from AI predictive maintenance solutions?

Most manufacturers see results from predictive maintenance in just a few months. If you plan early, there is less downtime. This helps make operational efficiency better. The maintenance team then gets more time to do important work. So, you get your money back faster and also see better results.

What are the main barriers to adopting AI predictive maintenance in the United States?

The biggest problems with using predictive maintenance in the U.S. are that it costs a lot, it is not easy to manage human resources, and doing data analysis can be tough. To fix this, the answers need to work well with the plans and systems that are already there.

What is AI predictive maintenance and how does it work in the manufacturing industry?

AI predictive maintenance uses data analytics, past data, and predictive models to help people see when a machine may stop working. This lets people find problems before they turn into big issues. In the manufacturing industry, predictive maintenance tools give real-time updates. They help people make the best use of their work so that machines last longer and work better.

Led the end-to-end development of mobile applications across fintech, health, e-commerce, and AI-powered domains using Flutter (Dart) and native Android (Kotlin/Java). Delivered performant and secure apps with seamless cross-platform UX, integrated real-time features using Firebase, and implemented third-party services such as Stripe for payments, OneSignal for notifications, and AI APIs for personalized experiences. As a team lead, managed a squad of developers, drove Agile processes, performed code reviews, and ensured delivery of high-quality, scalable apps. Focused on clean architecture (MVVM, BLoC), CI/CD automation, and optimized user retention through thoughtful UI/UX.