Traceability is rapidly becoming a key component of the manufacturing process for businesses across a wide range of industries. While some feel it only relates to products that may be recalled, such as food, vehicles, or aircraft, traceability should be integrated into all manufacturing processes. Considering the considerable economic, resource, and productivity benefits it brings, it’s easy to see why. Organizations can gain more granular control over their manufacturing process by deploying technologies that promote high-level tracking and tracing capabilities. This allows them to build safer, higher-quality products, as well as procedures that can be adjusted for continual improvement. Here are some statistics on which aspects of the manufacturing industry make crucial impacts.

- Value added in the Manufacturing market is projected to amount to US$15.36tn in 2024.

- A compound annual growth rate of 3.56% is expected (CAGR 2024–2028).

- Output in the Manufacturing market is projected to amount to US$79.86tn in 2024.

- A compound annual growth rate of 14.86% is expected (CAGR 2024–2028).

- The number of enterprises in the Manufacturing market is projected to amount to 7.11m in 2024.

- A compound annual growth rate of 14.17% is expected (CAGR 2024–2028).

- The number of employees in the Manufacturing market is projected to amount to 252.10m in 2024.

- A compound annual growth rate of 7.83% is expected (CAGR 2024–2028).

(Source)

What is Traceability in Manufacturing?

In manufacturing, traceability means being able to follow materials, parts, and finished goods (single, batch, lot, or package) all the way through the production process and into the supply chain. It has come a long way since the days when records were made by hand and tracking was done by hand. Manufacturers could keep track of anything that could be linked to a barcode, such as raw materials, parts, subcomponents, and final goods. Barcode technology changed the game.

Modern manufacturing tracking systems use advanced barcode, RFID, and data analytics technologies to help companies maintain quality, boost efficiency, and stay in compliance. These technologies give companies real-time production traceability, which means they can see information about the whole production process, not just the finished products. This is possible from the time raw materials and parts enter the facility until they are shipped out.

Important data that can (and should) be tracked involves:

- The place of manufacture of the product’s parts

- Product inspection notes

- Each workstation’s total time spent

- The complete schedule for the production

- Where the product will eventually end up

Simply said, traceability enables a definitive paper trail that records the origin, production, and delivery of your goods.

Also Read: Role of Traceability in Sustainable Supply Chain Management

Key Characteristics of Traceability

There are many characteristics of traceability available that play a vital role in the manufacturing industry. Here are some of the key characteristics of traceability mentioned below.

Identification: Identification is the key characteristic of Traceability that can be used to identify units/batches of all ingredients and products. This helps workers to get the ingredients that make the difference in the quality of the products.

Data collection: Traceability not only tracks the manufacturing process but also collects minute details or information about every manufacturing process and shows the errors in which process products get defective.

Linking ability: Linking is also a major characteristic of traceability as it allows linking to all data collected as part of a system. This helps to process the data by the existing system and find out the defective process.

Types of Traceable Manufacturing

There are mainly two types of traceable manufacturing. Here are the types of traceable manufacturing mentioned below.

Tracking of products

This type of traceable manufacturing lets you follow the path of a specific product through the supply chain. This allows us to find out the errors in logistics products in the manufacturing industry as most of the manufacturing industry uses logistics for production. (Alprazolam)

Tracing of products

This type of traceable manufacturing lets you identify the origin of a unit and/or batch of product located within the supply chain by referencing records held further along in the supply chain. This allows one to detect which particular process is faulty and can clove without wasting time to find out.

How does Traceability Work?

Most successful traceability systems are made up of two main parts. All of these are:

- Identifying and recording things correctly; and

- Keeping records centrally

The procedure necessitates the implementation of an identification or coding system that allows for the unique tagging of particular products, lots, or manufacturing from a certain geographic area. This includes using technology such as permanently labelling parts or components as they enter assembly or are delivered directly from the source. Organisations may use 2D bar codes, data matrix IDs, or RFID tags in this case.

When a product or component enters the production process, its ID is captured in real time and transferred to a central database, together with information about the job completed at each workstation. This is done at each station where the product or component passes, resulting in a detailed history of each individual product’s manufacturing journey.

This information can be reviewed with production planning systems to ensure that no steps are overlooked. Quality control can be conducted automatically at each stage of the process by comparing the part to a bill of materials to ensure that it arrived at the correct location and went through the proper assembly procedures.

When a product has a comprehensive manufacturing history, it is considered completely traceable. While traceability systems like the ones mentioned above were once expensive to deploy, more sophisticated systems are increasingly becoming more affordable.

Also Read our trending blog: Traceability Solutions for Supply Chains with Examples

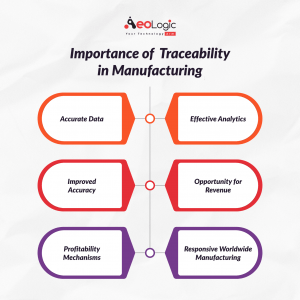

Why is Traceability Important in Manufacturing?

It’s becoming clear that traceability is the future of production as more industries and factories switch from traditional to digital processes. Technology has already changed the way things are made, which saves money and resources. But as industry 4.0 speeds up, companies can start to fully enjoy the many benefits of output with more technology by setting up strong traceability systems.

When companies start using traceability, they can start to benefit from having a lot more information and control over how their goods are made and sent to customers. Problems with production are easy to avoid, and if they do happen, it will be much easier to put out the fire. Product recalls can be a nightmare because they cost a lot of money and hurt a company’s image, reputation, and market share a lot. The Harvard Business Review warns that this multifaceted threat affects all businesses, no matter what field they are in.

Additionally, there are other important factors that support why tracking is important for businesses. Some of these are:

1. Accurate Data

Traceability of production begins with data collection. Not just any data, but significant information that generates valuable insights in addition to offering valuable information. The affixation of a barcode label or RFID device to any object presents a chance to transmit and collect data pertaining to a substance, component, or merchandise. In addition to price and origin, they are capable of storing certifications, material management, and tolerance information. In addition, they have the capability to monitor objects at critical junctures across the manufacturing process, enabling personnel to locate them, ascertain their previous location, or evaluate the consequences of workflow modifications.

2. Effective Analytics

Implementing robust data analytics software, manufacturing monitoring systems that collect data in real-time empower organizations to execute data-driven decisions with speed and precision. In addition, analytics enable the diagnosis of manufacturing problems and the testing of preventative measures that do not impede future production. Furthermore, the maintenance of an accurate genealogy database enables the identification of historical patterns, which can then serve as a catalyst for enhancing processes.

3. Improved Accuracy

Automated internal traceability systems improve the accuracy of all production and business forecasting by providing real-time data and analytics on equipment, labor, inventory, process change, and profitability, among others. It also provides precise genealogical information, location, and origin when it is most important to prevent or limit liability. Collecting and analyzing data manually is less precise and timely, and it hinders the collaborative efforts made possible by “one version of the truth” reporting and readily shareable data.

4. Opportunity for Revenue

Customers find optimal manufacturing processes to be a significant selling point. Flexibility and production agility are the same. Traceability in manufacturing enables all three and can serve as a genuine differentiator in the marketplace. Organizations experiencing expansion can utilize the analytical functionalities of production traceability software and applications to test new equipment, scalability, and process modifications without causing operational disruptions.

5. Profitability Mechanisms

Profitability is predicated on operational efficiency, and contemporary manufacturing monitoring systems provide an organization with an expanded array of profit enhancement levers, including quality control and production efficiency opportunities. Traceability of production reduces the financial risk associated with regulatory noncompliance, larceny, and recalls, as previously stated.

6. Responsive Worldwide Manufacturing

Organizations are now required to maintain global supply, manufacturing, and distribution chains due to the expansion of globalization. Throughout those tens of thousands of miles, much could potentially fail. Traceability aids in mitigating the risk of catastrophe and equips the necessary resources to promptly address issues as they arise.

Also Read our trending blog: Traceability Solutions for Supply Chains with Examples

Steps to Trace a Product in the Manufacturing Industry

Here are some steps mentioned that can be used to trace a product in the manufacturing industry.

Step 1. First of all, you’ll typically need to assign each product discrete part marks or individual component-level marks (like serial numbers) during the manufacturing process.

Step 2. Work with your supplier to find equipment that will work best for your particular product and process.

Step 3. Use tools and digital resources that track parts and products to monitor your production line.

Step 4. IoT devices such as Barcodes and scanners can be used to easily track products and record relevant data in real-time.

Limitations of Traceability in Manufacturing

While traceability is an important aspect of supply chain management in the manufacturing industry, there are several limitations and challenges faced by manufacturers. Here are some of the limitations of traceability mentioned.

- Sometimes the lack of transparency and visibility of certain stages in the supply chain, data entry errors, system failures, or non-standardized data formats limit the effectiveness of traceability.

- There are sometimes complex processes in manufacturing so extracting detailed information from secondary or tertiary suppliers to trace the origin and movement of each component or ingredient can be particularly difficult.

- Implementing and maintaining traceability systems requires significant investment in technology, infrastructure, and personnel. It can be too costly for small manufacturers as they do not have sufficient money to afford it.

Final Words

Aeologic Technologies helps businesses set up high-performance, well-integrated traceability systems by giving them a high-performance option. Companies that want to join the digital revolution can do so by working with us. We offer them a fully customizable IIoT solution that lets them take advantage of the new possibilities that come with living in the digital world. You can get in touch with us if you want to know more about how Aeologic can change the way you make things.