If anything helps to increase the efficiency of your business in today’s world, it is automation. Automation solutions are great to fully optimize human potential by freeing them up to focus on high-level tasks. However, automation still needs to be enhanced with the integration of some advanced and potential technology, and IoT seems to be the best technology that can surely enhance automation solutions more than ever before. Businesses are rapidly investing in IoT automation solutions in 2025 to make their businesses grow and stay not just one step but many steps ahead of the others.

In 2025, companies are making significant investments in IoT automation in an effort to increase productivity, cut expenses, and enhance customer satisfaction. By automating repetitive operations, optimizing resource allocation, and facilitating real-time data collecting and analysis, these technologies eventually increase productivity and profitability.

IoT solutions are essential to sustainability initiatives since it help companies lower their carbon footprints and energy usage. Machines with IoT automation capabilities can drastically lower operating expenses for companies. Businesses can enhance production and reduce labor costs by automating procedures.

Smart inventory systems, for example, alert managers when supplies are running short, preventing unnecessary inventory expenses. There are many more benefits of IoT automation for businesses. It helps them grow now and also keeps them ready for the future.

Key Statistics Related to IoT Automation

The global IoT automation market size is projected to reach $629.5 billion by 2025. This represents a significant growth from $535.97 billion in 2024, with a compound annual growth rate (CAGR) of 17.5%. This growth is driven by the proliferation of connected devices, data analytics, and increasing adoption in areas like industrial automation, smart cities, and healthcare.

While the adoption rate of IoT automation solutions 2025 varies by company size, large enterprises have the highest adoption rate (48%), followed by medium-sized enterprises (37%) and small enterprises (26%).

IoT in industrial automation can significantly reduce maintenance costs (20-25%), lower equipment breakdowns (70-75%), and cut downtime (35-45%).

Also Read: How IoT Software Solutions Are Transforming Enterprises

Role of IoT Automation Solutions for Businesses in 2025?

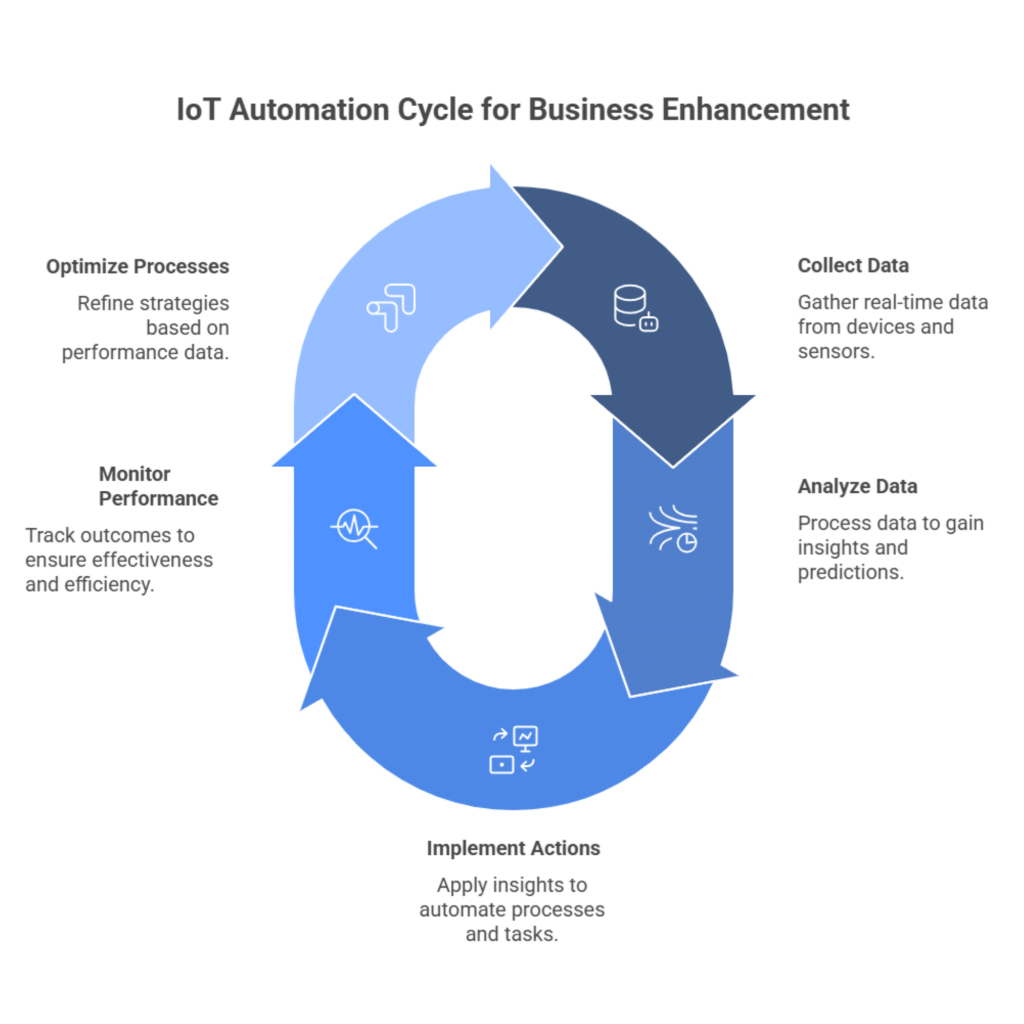

The IoT automation solutions refer to the software and hardware solutions developed through the involvement of IoT-powered devices, such as sensors, and the integration of AI algorithms with machine learning capabilities to automate tasks and improve efficiency for businesses, organizations, and individuals at various levels. Real-time data collection is one of the key advantages of IoT technology, facilitating streamlined operations, predictive maintenance, and process optimization.

These advantages will be further amplified and enhanced by the AI algorithm and IoT integration, which will result in smarter, more autonomous systems and improved customer experiences. Surely, IoT automation is so great that businesses are forced to make investments in this year and for many years.

Also Read: Top Things To Look For In An IoT Development Company

Application of IoT Automation for Businesses 2025

There are various applications of IoT for automation, as here are a few key applications mentioned below.

Predictive Maintenance

The IoT automation can enable predictive maintenance for businesses as the AI and ML algorithms with the IoT integration enables data collection and analysis for predictive analytics automatically. Predictive maintenance enables businesses to detect potential failures in the initial stage to avoid any downtime for the businesses.

Smart and Automated Manufacturing

IoT-powered automation can establish smart and automated manufacturing processes. The IoT automation-powered sensors, devices, can enable the monitoring of systems automatically and also enable automation for routine tasks that reduce the burden of manufacturing businesses with more accuracy.

Energy Management

The business processes involve various resources and energy consumption as it is important to implement energy management solutions. The IoT automation-powered solutions can automatically detect the energy consumption and needed amount of energy on a specific task. It turns off the energy supply automatically whenever the consumption increases beyond the need and enhances the energy management for the businesses.

Quality Control and Inspection

Quality control and inspection always remain the top priority for businesses as IoT automation can enhance these aspects too. The IoT automation-powered camera, sensors, and AI-powered algorithm can automatically inspect and detect quality degradation. Also, it provides solutions to make quality better. So quality management is another key application of IoT automation.

Controlling Remote Monitoring

The key uses of IoT in industrial automation are remote monitoring and control. IoT technologies provide insights on device networks across manufacturing facilities and industrial complexes, therefore supporting remote supervision and equipment and process control. Improved safety, more uptime, and significant cost savings follow from this capacity.

IoT lets AI and automated equipment run in warehouses, therefore lowering the accident and injury hazards. Real-time tracking and monitoring made possible by IoT technologies greatly improve operational efficiency and inventory control.

Improves Operational Effectiveness

IoT is essential for improving operational efficiency by means of data collecting and transmission between devices meant to maximize operations. Improved efficiency, safety, and decision-making procedures follow from this connectivity.

Real-time monitoring and data analysis helps companies to find manufacturing process bottlenecks, hence improving operational efficiency and productivity.

Real-Time Data Analytics

IoT’s real-time data analytics offers major advantages, including predictive maintenance and process automation, which finally results in best operations. Further improving monitoring and optimization capacity are digital twins, which use real-time data to generate virtual replicas of physical assets. Data is handled and analyzed at the edge of smart industrial IoT systems, therefore enabling faster insights and decisions.

IoT solutions in industrial environments allow real-time inventory tracking and operation optimization via improved data analytics. This capacity lets producers compile information, instantly evaluate it, and make wise decisions based on it that increase output and efficiency.

Also Read: IoT Solutions for Real-Time Tracking of Media Equipment

Benefits of IoT Automation That Make Businesses to Invest In It

There are various benefits of IoT automation that make businesses invest in it. Here are the key benefits mentioned below.

Improved Safety

Safety is an important aspect of businesses as it is about the workers’ lives. The IoT automation system continuously monitors the risk factors and if any hazardous activity, risk issues, accidents, etc occurs. This provides safety precautions and tips to help you stay calm in a panic situation. This also recommends the right wearable safety gear for the workers, which enables them to work without any fear.

Data Security

IoT automation also enhances data security for businesses. IoT automation comprises AI and ML abilities that help to detect patterns of data and detect any type of vulnerabilities very early. This helps to take security measures and activate cybersecurity that overall safeguards the data before any potential damage.

Lower Operating Costs

The businesses consist of various tasks that are either too difficult or too repetitive. This creates frustration, extra labor charges, consumes unnecessary time, etc for the companies. The IoT automation solutions enable automation for this type of task with more accuracy and consistency than human employees. This not only enhances efficiency but also saves unnecessary expenses.

Visibility of Supply Chain

The IoT is known for its real-time monitoring ability as the IoT automation solutions can enhance the real-time visibility for various processes such as inventory stock level monitoring, error or fault monitoring, productivity monitoring, to enhance the overall supply chain management. Real-time visibility with automation capability can make the best decision for the benefit of your business.

Better Productivity Rate

IoT automation solutions help businesses to deal with various issues related to various departments. This overall increases productivity with automation and better decision-making ability. For example, Siemens has increased productivity by 40% through IoT technology, achieving a 99% reduction in production errors.

| Benefit | How It Helps Your Business | Real-Life Example |

|---|---|---|

| Cost Savings | Cuts down manual labor and reduces errors | Automated lighting reduces electricity bills |

| Increased Efficiency | Automates routine tasks and speeds up processes | Smart sensors speed up production lines |

| Real-Time Data & Insights | Gives instant updates to improve decision-making | Live inventory tracking prevents stockouts |

| Improved Customer Experience | Enables faster service and personalization | Personalized offers sent via smart devices |

| Better Asset Tracking | Helps you monitor and manage equipment or goods easily | RFID tags track shipments in real time |

| Enhanced Security | Monitors for threats and sends instant alerts | IoT cameras detect unauthorized access |

| Predictive Maintenance | Spots problems before they cause downtime | Machines alert staff before breakdowns |

| Scalability | Easily expands as your business grows | Add new IoT devices without big changes |

| Environmental Benefits | Optimizes energy and resource use | Smart meters lower water and power waste |

| Future-Proofing | Keeps your business ready for new tech and market changes | Updates systems automatically |

Also Read: Discover the Best IoT Solutions for Your Business Today

Challenges and Solutions in IoT Automation

Despite its many advantages and uses across industries, IoT automation still poses multiple challenges that your firm must address when deploying:

Data Privacy and Security

With so many devices, communication protocols, software systems, and cloud servers included, IoT architecture is large and sophisticated. If inadequate security measures are included in any piece of hardware, firmware, or software, it can become a possible gateway for cyber threats.

Moreover, a vast network of IoT devices can generate enormous data volumes transferred between physical objects and a central system. Data could be prone to illegal access both at rest and in transit without strong security systems. Not to mention that other industries, like finance or healthcare, have to deal with private information. Not only expose private information, but it also compromises the overall IoT system’s performance due to breaches in one device.

Solutions:

Every layer of the IoT system should have robust security mechanisms in order to protect data and guarantee adherence with privacy rules. They cover strong authentication systems, safe communication techniques, data encryption, and frequent security upgrades. Moreover, give security top attention when developing an IoT system. This lets development teams include security at every stage of IoT system implementation and evolution.

Interoperability:

Consider a complete IoT automation system as the host of a conference assigned to enable participant contact and teamwork. These players, sometimes known as physical equipment and software platforms, have varied functions, hold unique knowledge, and speak several languages (also known as communication protocols).

These “participants” find it difficult to operate smoothly, nevertheless, without common procedures and standards. A lighting system from one brand could not integrate, for instance, with a security system from another. We call this difficulty “interoperability.”

Solutions:

When building IoT infrastructure, give devices and platforms supporting industry-wide standards and open communication protocols top priority. This minimizes integration costs and gives users flexibility while allowing the components of your IoT system to run without problems.

High Beginning Investment

Creating and implementing an IoT-based automation system calls for time and significant initial expenses. Hardware components (e.g., sensors, microcontrollers), firmware, software, cloud services, connectivity networks (e.g., Wi-Fi, LoRaWAN), security, and integration with your legacy system define these expenses most of the time. Not to mention that the whole IoT development cost might be added by elements including maintenance, scalability, and customizing. Furthermore, technological and business problems can IoT initiatives to endure longer than expected.

Solutions:

Development of a Minimum Viable Product (MVP) to test necessary features and interface with your present system could help to perhaps lower expenses. To cut development time and expenses, also make use of off-the-shelf alternatives including popular cloud platforms or pre-certified hardware components Moreover, give security top priority and make scalability plans starting with the IoT development project. This helps you prevent major costs related to future expansion and data leaks.

Looking for? Top IoT Solution Provider Companies in 2025

Cost to Develop IoT Automation Solutions In 2025

There is no estimated cost for IoT automation. Here is the cost breakdown of IoT and automation, individually mentioned below.

Cost of IoT Factors

IoT development can be expensive, but understanding costs upfront helps you plan better. Here’s a quick breakdown of what to expect when building IoT solutions:

-

- Hardware Costs: Start at $30,000 for basic setups. Sensors, WiFi modules, and microcontrollers are key components.

-

- Software Development: Begins at $50,000. Includes cloud services, app development, and analytics.

-

- Connectivity: Costs $4–$12 per device annually, depending on the network type (e.g., LoRaWAN, cellular).

-

- About 30% of IoT expenses come from hardware. Understanding these costs is crucial for accurate budgeting and finding ways to save.

-

- Use sensors to monitor equipment and schedule maintenance before issues arise. This can help avoid downtime, which can cost businesses $100,000 to $300,000 per hour.

Cost of Industrial Automation

Implementing industrial automation comes with several cost components you’ll need to plan for. Here’s a breakdown of the key expenses.

-

- Software costs can range from $10,000 to $50,000, depending on the provider and the features you need.

-

- Professional system integrators usually charge between $100 and $200 per hour for installation and integration services.

-

- Training programs generally cost between $5,000 and $10,000 per employee, depending on the training depth and required skills.

-

- A partially automated system might cost around $200,000, while fully automating a line can exceed $500,000, depending on the equipment and system complexity.

Final Take

The IoT automation future looks promising with the various key trends like 5G connectivity, digital twins, AI integration, IoT device upgradation and advancement, integration of cloud for better data analytics, etc. With the various key benefits and applications, IoT automation is driving the future of businesses. The IoT powered automation is becoming the great tools for business to get the path of success and long run opportunities in the competitive market. These solutions not only enhance businesses but also help to make global development to change the fortune of many other sectors too.

Aeologic Technologies team has a great deal of experience with IoT solutions. When you are ready to take the next step, reach out to us today so we can discuss your requirements and targets.

FAQs

How does IoT automation help my business save money?

IoT automation reduces manual work, prevents errors, and cuts down on waste—helping your business lower its operating costs.

Will IoT automation make my business more efficient?

Yes, IoT systems work 24/7, collect real-time data, and help you quickly spot and fix problems, making your business run smoother.

Is IoT automation safe for my company data?

Modern IoT solutions use strong security tools to protect your data and keep your business information safe.

Can IoT automation help me serve customers better?

Absolutely. IoT helps you track inventory, speed up service, and personalize customer experiences, so your customers stay happy.

Is investing in IoT a smart move for the future?

Yes, IoT automation keeps your business updated with the latest technology, making it ready to compete and grow in the coming years.

Can IoT automation help reduce downtime in my business?

Yes, IoT devices can spot problems early and alert you before something breaks down, so you avoid costly downtime.

Is IoT automation difficult to set up?

Most IoT solutions are user-friendly and can be set up with help from experts, so you don’t need to worry about complicated installation.

Will IoT automation work with my existing systems?

Many IoT solutions are designed to connect with your current systems, making it easy to upgrade without starting over.

How can IoT automation improve decision-making?

IoT gives you real-time data and insights, so you can make smarter and faster business decisions.

Does IoT automation support business growth?

Yes, IoT helps you scale by making daily tasks easier, giving you more time and resources to grow your business.

I’m Deepika Pandey, an SEO strategist and content writer with 6+ years of experience. I create SEO-friendly content that drives traffic and engages readers. I combine data insights with creativity to help businesses grow their online presence effectively.