Introduction

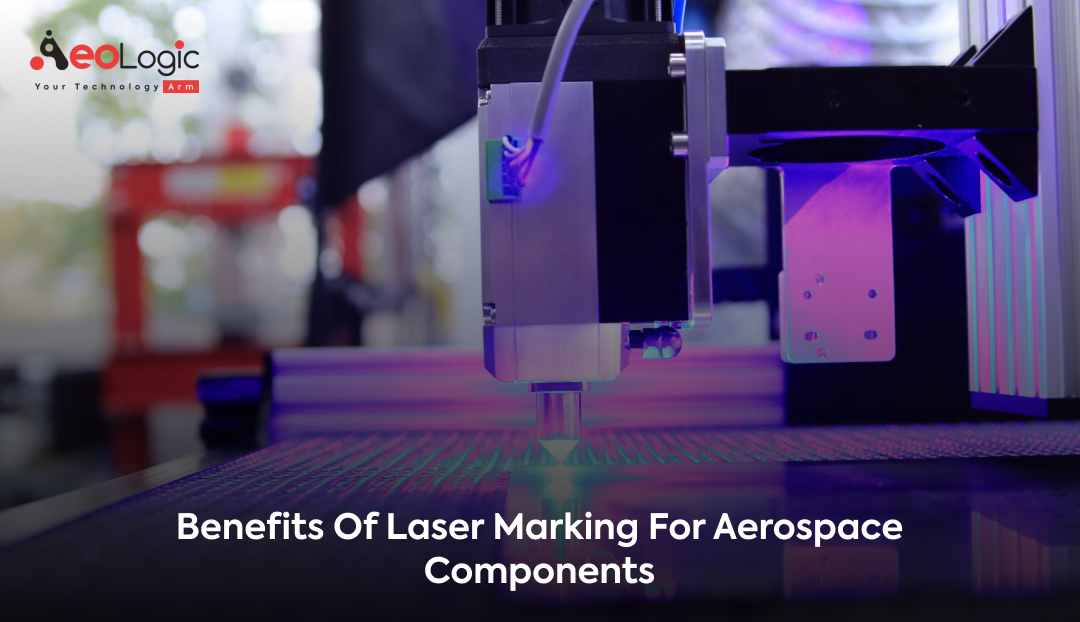

Laser marking is a technology that’s frequently used in the aerospace assiduity to engrave or mark factors with great perfection. It utilizes laser shafts to produce endless markings on different aerospace materials, ensuring traceability and compliance with assiduity norms. Precision, continuity, and traceability are critical factors impacting safety and effectiveness in aerospace engineering. As technology advances, sectors are constantly looking for new ways to ameliorate their processes. Laser marking has surfaced as a game changer for marking aerospace factors, with multitudinous advantages over traditional marking ways. In this blog, we ’ll look at the benefits of laser marking for aerospace components and how it has changed the assiduity.

Also read: The Role of Technology in the Future of Aviation

The Process is Clean and Eco-Friendly for Laser Marking for Aerospace Components

Other marking processes, such as inkjet or chemical drawing, use inks and chemicals in their marking which not only are precious consumables for the business, but have a negative effect on the terrain. Laser marking, on the other hand, doesn’t use any consumables making is clean, affordable and energy effective. It also eliminates costs and time-out associated with cleaning, fixing or powering printers. While markers can peel off or come damaged over time, laser marking, provides endless identification for corridor and doesn’t have to be performed multiple times.

Because the laser marking for aerospace components process is non-contact, laser marking ensures clean processing with minimum impurity. Where publishing systems will burn down the material by marking, the damage-free process involves minimum or no material penetration.

Benefits of Laser Marking for Aerospace Components

Unmatched Precision

Precision is essential in aerospace engineering. The delicacy and thickness of element markings are critical for ensuring proper operation and life. Laser marking for aerospace components by companies offers unexampled perfection, allowing you to mark factors with inconceivable detail and intricacy. Because of the laser’s focused ray, microscopically precise markings are possible, making it ideal for intricate periodical figures, part canons, and indeed barcodes.

Laser marking’s perfection reduces the possibility of human error and ensures flawless integration into complex aerospace systems.

Enhanced Continuity

Aerospace factors operate in harsh conditions similar as extreme temperatures, pressure oscillations, and chemical and sharp element exposure. Stickers and published markers, for illustration, may wear off or fade over time, jeopardising traceability and safety. Laser marking, on the other hand, creates endless markings by altering the material’s face, making it largely resistant to bruise, chemicals, and environmental factors. The increased continuity ensures that critical information remains saved throughout the element’s lifetime.

Non-Destructive Process

The fact that laser marking is non-destructive is a significant advantage. Unlike traditional drawing styles, which may affect in the junking of material or physical damage to the element, laser marking uses a focused laser of light to mark the face without altering its physical parcels. This is especially important for aerospace factors, whose structural integrity must be saved for safe and effective operation.

High- Speed and Effectiveness

Time is of the substance in the aerospace assiduity. Laser marking machines are designed to operate at high pets. Therefore, allowing for quick and effective element marking. Higher productivity is also one of the characteristics of laser marking systems’ robotization capabilities. The capability to mark multiple factors at the same time increases outturn significantly, reducing product time and costs.

Environmentally Conscious

As environmental enterprises come more burning, diligence are looking for environmentally friendly results. Laser marking meets this growing demand because it’s an environmentally friendly process. Unlike traditional marking styles that use chemicals and waste resources, laser marking produces little waste and doesn’t bear any fresh substances for the marking process. This reduces the assiduity’s environmental footmark and helps to promote sustainable manufacturing practices.

Flexibility with Materials

Aerospace factors are made from a variety of materials, each with its own set of parcels and marking challenges. Laser marking technology is highly versatile, able of marking a wide range of materials including essence, mixes, plastics, pottery, and others. Because of its rigidity, aerospace manufacturers can streamline their marking processes for different resources, barring the need for multiple marking systems and simplifying product workflows.

Increased Traceability

Traceability is an important aspect of aerospace manufacturing, particularly for quality control and assiduity compliance. Laser marking allows for clear and endless element identification, making it easier to track and trace each item throughout its lifecycle. This data simplifies conservation, repairs, and recalls, allowing any issues to be addressed quickly and directly.

Also read: Role of Information Technology in Aviation Security

Conclusion

Laser marking has surfaced as a important tool to ameliorate productivity, safety, and effectiveness in the aerospace assiduity, which is at the van of technological advancements. Furthermore, laser marking helps in converting aerospace factors due to its unequaled perfection, continuity, and non-destructive nature. Laser marking has long- term benefits for traceability, quality control, and sustainability beyond the manufacturing process. As the aerospace assiduity pushes the boundaries of invention, laser marking remains a critical asset, propelling it towards a safer and more effective future.