Manufacturing Automation is Transforming the Way Things are Made in India. Today, manual labor and inefficient production processes are a thing of the past. The manufacturing industry in India is witnessing a great transformation due to the rise of automation. This article looks at how automation is redefining the manufacturing landscape in India and what this technology has to offer.

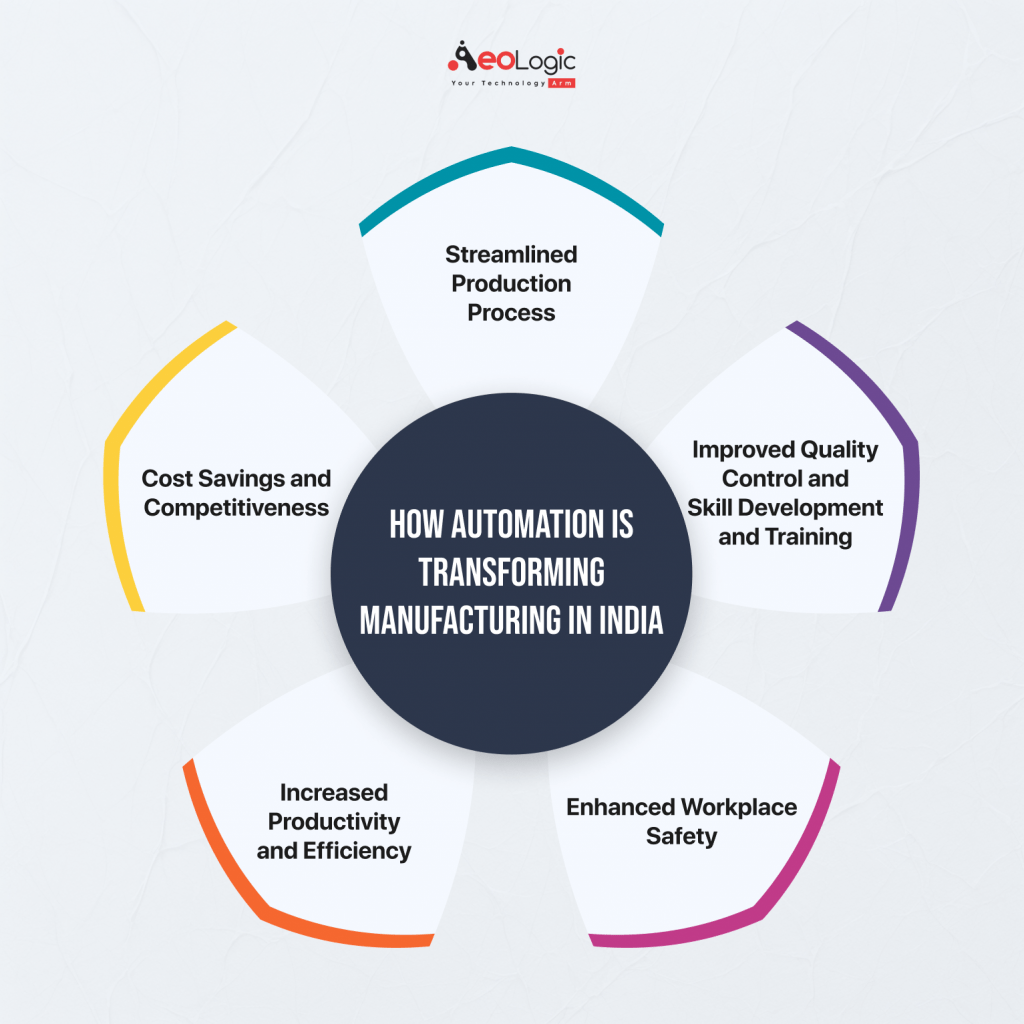

Streamlined Production Process

The major benefit of automation in the manufacturing sector is the improvement of production-related processes. Robotics and computerised machines, for example perform precise and consistent tasks. This increases the quality of product and reduces chances for errors occur.

For example, various firms such as automobile manufacturing, electronics and textiles have all embraced automation to increase the effectiveness of their production lines through India. With automated machines, production can be done continuously as the machines do not need to rest, which increases efficiency and output. This not only enables manufacturers to meet increased demand but also cuts production costs in the end.

Also Read: Role of Industrial Automation in Product Traceability

Improved Quality Control

In manufacturing, quality control is crucial and automation aids to that. In this era, automated systems have the capacity to carry out very complex inspections and tests for products with a higher degree of accuracy in error identification or deviation from specifications. These assist in ensuring constant product quality by manufactures and it is vital for customer contentment and competitive advantage.

Quality control through automation in Indian manufacturing. Automated inspection systems and real-time analysis of data enable the manufacturers to identify and correct any quality problem on time thereby reducing the chances of having defective products reach customers.

Enhanced Workplace Safety

Automation in manufacturing has similarly lead to huge betterment of safety at the workplace. Robots and automated machinery have taken over from what used to be very dangerous and monotonous responsibilities performed by human labor. This lowers the incidents and liability incidences and provides a safe workforce environment.

India has experienced significant improvements in workplace safety through automation, especially in industries such as that of heavy machinery and dangerous chemical production. Manufacturers do not only save their workers but also protect themselves from financial and legal implications resulting from workplace mishaps by assigning dangerous activities to automated systems.

Increased Productivity and Efficiency

Manufacturing automation implies increased productivity and efficiency. With the robots and machines being automated, they can work throughout with no fatigue hence increased production rates. In addition, they can do work right first time with more certainty and accuracy, which means less waste in the form of reworking.

As a result, manufacturers in India have gone high tech to raise the bar in their productivity. This is especially useful in production of high volumes of products within a short time in promising industries. The promise of higher productivity gains lies ahead as automation technologies continue to advance. According to the source, more advancements will be made with time and this will help enhance productivity by far.

Also Read: The Future of Big Data in Automation Industry

Cost Savings and Competitiveness

Manufacturers are seeking to reduce the production costs and automation happens to be a significant tool that can enhance this goal. This makes it possible to rely on automated systems that can work perfectly with minimal supervision thus cutting the cost of labor involved in manual labour. Automation also reduces the cost of operations by minimizing material wastes and energy uses.

Automation is what makes Indian manufacturers cost competitive internationally. By keeping low production cost, they can sell their products at competitive prices, boosting their clientele and market coverage. This in turn has added to the general growth of the Indian manufacturing sector.

Skill Development and Training

However, automation in manufacturing decreases manual labor demand in some areas; it also presents new channels of skill development and training. As companies adopt automation technologies, they need technicians and engineers who are skilled in designing, operating and maintenance of these systems.

Automation and robotics are becoming increasingly popular in the field of professional practice, especially in India. This demand is being recognized by educational institutions and training centers, who are offering courses and programs that prepare people with the required skills. This not only bridges the skill gap, but also equips the workforce adjust to the transforming world of manufacturing.

Sustainability and Environmental Impact

The environmental implications of automation in the manufacturing sector are also positive. Automation ensures that manufacturers reduce wastage and optimize their production processes, minimizing the ecological footprint of any manufacturing operation. Moreover, automation embodies energy-saving initiatives that also minimize negative environmental influence.

For instance, the only industrial sectors in India, where automation has been put in use to link with sustainability targets include renewable energy and green production. Such companies become environmental responsible and also help in adding value to the consumers who are much concerned with the green product.

Also Read: How AI is Improving Agriculture Sustainability in India

Challenges and Considerations

While automation brings numerous benefits to manufacturing in India, it is not without its challenges and considerations:

Initial Investment: However, adopting automation technologies may require significant initial costs especially for the small and medium-sized enterprises providing a hurdle.

Workforce Transition: When automation comes in the managers need to install and maintain the machines which may lead them giving a chance to delegation of worker’s functions that translates unemployment issues. For a successful transitioning, careful management has to be done which involves reskilling and upskilling.

Maintenance and Downtime: It needs to be maintained at regular intervals and if it camps in because of technical problem, it will effect on production scheduling. It is therefore necessary for the manufacturers to establish strong maintenance plans.

Data Security: Increased automation means that more data Is produced and there is a lot of connectivity. Cyber threats are the major dangers-prone to security sensitive manufacturing data.

The Future of Automation in Indian Manufacturing.

Automation in manufacturing: Indian manufacturing sector poised for takeoff. With the increasing development of technology, automation will become cheaper and available to a growing number of different organizations. Automation will enable smaller manufacturers to improve their competencies.

Furthermore, the inclusion of artificial intelligence (AI) and the Internet of Things (IoT) will also improve functionality for automated systems. This trends will continue to emerge more in future whereby manufacturers will constantly be optimizing their operations through predictive maintenance, real-time monitoring and data-driven decision-making.

Also Read – Digital Adoption Advantages for Manufacturers

Final Words

In the long run, Indian industry landscapes are being shaped by automation in manufacturing. The advantages of automation are apparent in the modernized production processes up through quality control and safety as well as higher productivity. Although hurdles have to be faced, appropriate and well-thought strategies can triumph over them.