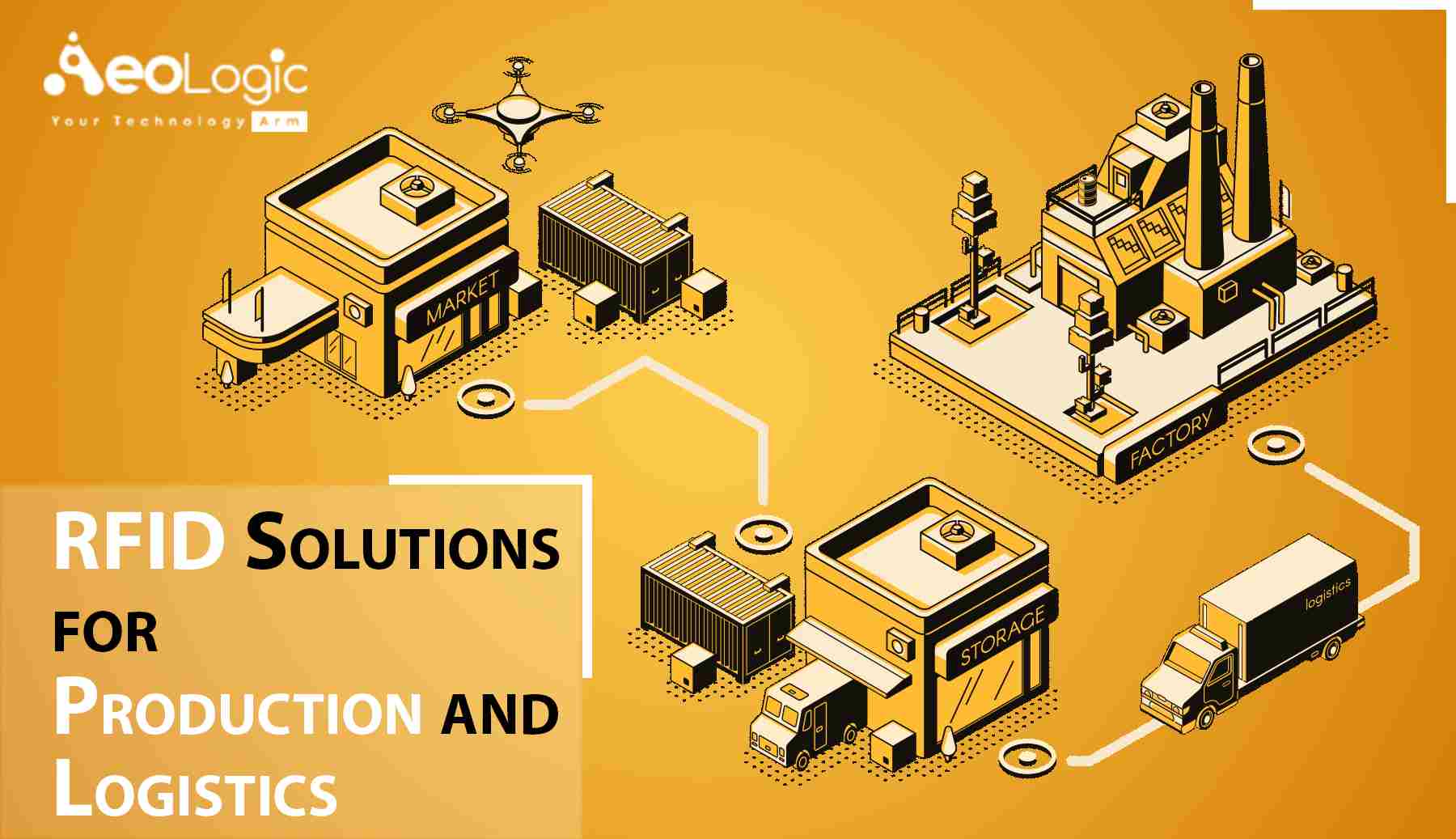

Radiofrequency identification(RFID) solutions have played an important role in transforming the industries phenomenally around the globe. It has made the process of workflows effective and efficient with its highly beneficial functionalities of tracking, monitoring, and identifying the objects accurately.

The world of production and logistics has reaped many benefits from RFID solutions in this blog you’ll come to know the RFID solutions for production and logistics.

What are the solutions RFID Technology Offers?

The radio frequency identification(RFID) technology offers the following solutions:

1. End-to-end Tracking: With the implementation of RFID in the workflow both the business owner and the customer will be able to track the shipment. This will give the business owner a better vision to improve the routing of the products and customers will also be able to be updated and will feel connected to the shipment.

2. Saving Time: RFID reader enables in reading the RFID tags attached to the objects in seconds so even if the volume of shipment is huge the usage of RFID technology will take less time compared to any other mode of identification.

3. Enhancement in Surety: By implementing RFID technology in production and logistics both the business owner and the customers will be able to experience a sense of surety when it comes to ensuring the quality, quantity, and availability of the object.

4. More than just products: The radio frequency identification (RFID) technology is not only limited to be used on non-living items rather it can be used on birds and animals as well. This enables the businesses dealing with birds and animals to optimize their work efficiency.

In extension to this following are some points the radio frequency identification (RFID) technology involves:

1) There are two types of tags the first one is read-only tags and the second one is read-write tags. The read-only tags can add the data only once where on the other hand the read-write tags can add data more than once.

2) The read-only tags are used because they are cheaper and they’re also more efficient than barcodes and still provide protection against counterfeiting.

3) With read-write tags the information can be added as many times as users like. At the time when items arrive at each warehouse and the result of quality inspections.

4) Radiofrequency identification(RFID) technology involves the usage of different radio frequencies. There are three types of ranges low frequency, high frequency, and ultra-high frequency (UHF). UHF is the best if the user wants to read tags from far away like over 15 meters UHF is good for reading tags on trucks passing through a checkpoint.

5) The UHF can’t pass through liquids or metals so liquid medicines can’t use it the user needs to use low frequency for those.

6) The high frequencies are used when the distance is neither too big nor too small like employees’ ID cards that open office doors, counting items on a conveyor belt, or for detecting items being stolen from the retail store.

Conclusion:

To conclude we’ll say that radio frequency identification(RFID) technology offers astonishing solutions that are capable of enhancing the effectiveness and efficiency of your business.

Are you looking to get radio frequency identification (RFID) in your supply chain and logistics business? If yes so please feel free to contact us at support@aeologic.com

Manoj Kumar is a seasoned Digital Marketing Manager and passionate Tech Blogger with deep expertise in SEO, AI trends, and emerging digital technologies. He writes about innovative solutions that drive growth and transformation across industry.

Featured on – YOURSTORY | TECHSLING | ELEARNINGINDUSTRY | DATASCIENCECENTRAL | TIMESOFINDIA | MEDIUM | DATAFLOQ