Everyone wants a nice, neat and organized warehouse. But is it possible to have a clean warehouse without proper logistic planning and management? Being able to find all the items you need in your warehouse can be a challenging and time consuming task if they are not organized properly. In this article we will give you a brief introduction on what warehouse logistics is, why you should care about it, and how it can help you in your business.

Warehouse logistics is a field of management that involves the storage, distribution, and loading (SDL) of goods. Logistics are the operations that support and move goods from one location to another in accordance with production schedules or customer orders. The warehouse logistics field consists of several interrelated disciplines. Some common fields in this discipline include transportation, freight forwarding, receiving, distribution and re-distribution.

Introduction

The world of warehouse logistics is not one that’s been well-defined. There are many different terms used to describe the process by which goods are moved from their point of origin to their final destination, but none of them quite captures the essence of how this works. That’s why we’ve decided to make a name for ourselves by creating our own definition:

Warehouse Logistics refers to how companies move products from manufacturers or suppliers through their supply chain. It includes everything from planning and scheduling operations to managing supply chains and data centers; all in order for retailers or manufacturers’ warehouses stay organized, efficient and effective at what they do best: moving inventory efficiently throughout their facilities so that customers receive them when needed most!”

What is Warehouse Logistics?

Warehouse logistics is the process of moving goods from the point of origin to the point of consumption. This can be broken down into two categories: internal and external warehouse logistics.

Internal Warehouse Logistics refers to the movement of goods within a company, while external Warehouse Logistics involves moving goods from one location to another location. In both cases, there are many challenges that must be overcome in order for these processes not only work well but also contribute positively towards overall profitability for companies involved in this type of activity.

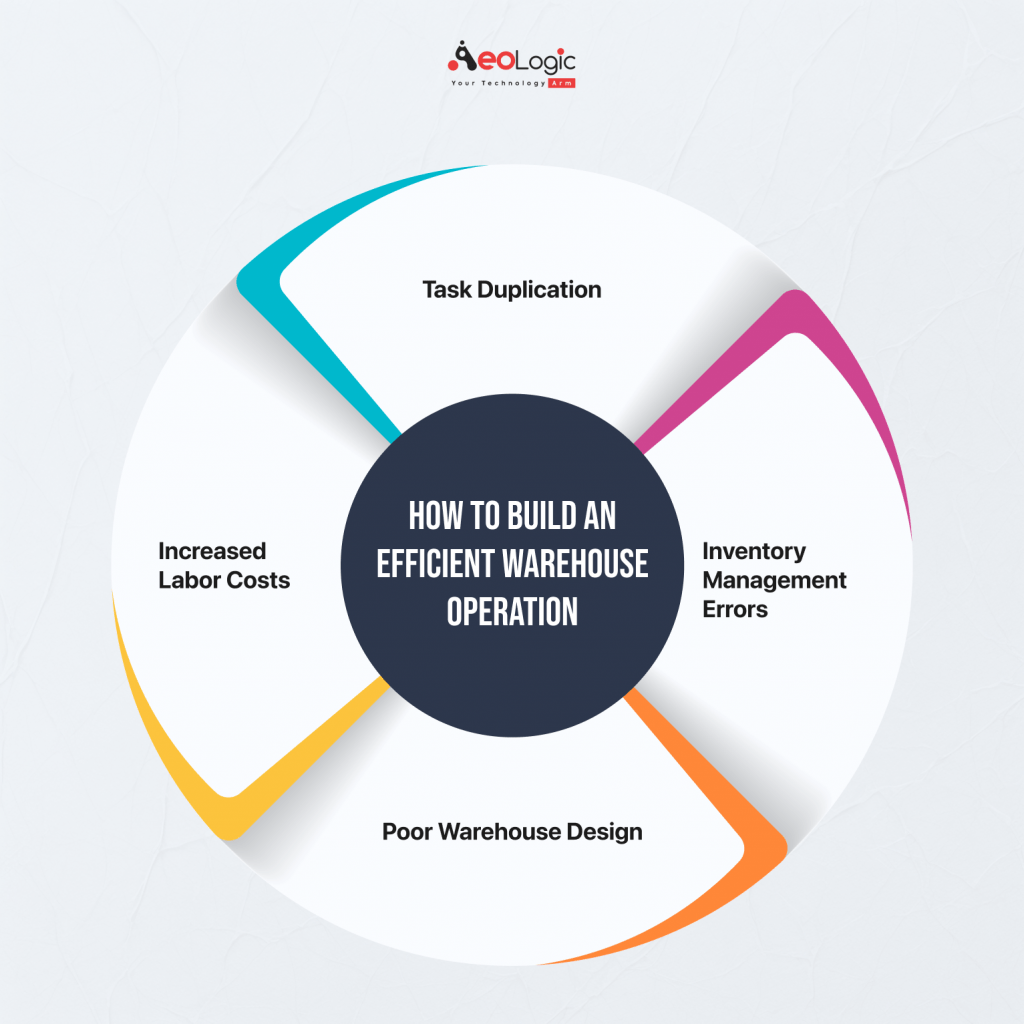

How to Build an Efficient Warehouse Operation

To build a warehouse operation that’s efficient and cost-effective, you’ll need to use technology to automate processes and reduce manual labor. You can also use a warehouse management system (WMS) or other software that allows you to track inventory and shipments easily.

You should consider using:

- Mobile solutions like handheld barcode scanners.

- Handheld devices like mobile printers.

Also Read: The Role of AI in Education And Learning: Just Promises Or Revolution

Challenges

Managing warehouse logistics operations entails a plethora of processes, programmed, and individuals. As a result, keeping physical goods flowing, providing real-time information to customers, and dealing with multiple warehousing issues at the same time may present unexpected challenges.

Here are some of the most significant challenges that warehousing and logistics professionals face on a daily basis:

Task Duplication

While digitization is increasing in many industries, many warehouses still use paper-based data entry processes. Continuing to use inefficient manual processes wastes time and can raise labor costs. Barcode technology can aid in the elimination of these redundant tasks. Automated systems can streamline warehousing operations and eliminate manual labor.

Inventory Management Errors

Inventory errors is at the heart of several difficult warehouse logistics issues. Each item entering the warehouse should have a designated storage location; otherwise, workers may waste time travelling to the wrong location. Manual inventory updates result in inaccurate information and more human errors.

Poor Warehouse Design

Overcoming these challenges may necessitate a foray into the WMS software market. By organizing and managing activities, WMS solutions allow you to optimize your warehouse layout and increase the speed of all your processes.

Increased Labor Costs

According to the Third-Party Logistics Warehouse Benchmark report, labour costs account for nearly 40% of total warehouse fulfilment costs for 57% of 3PLs. While 18% say it is 60-70% of their total costs.

Benefits of Using Warehouse Logistics Software

The benefits of warehouse logistics software include:

- Reduce costs: Warehouse management software can help you track inventory and cost of goods sold (COGS) in real-time, which will enable you to identify inefficient processes more easily. This also helps you make better decisions about where to allocate your resources so that they’re used most effectively at any given time.

- Increase efficiency: Increase efficiency through increased productivity levels within the organization and between departments or locations. Having access to real-time data allows employees with specialized skillsets or knowledge bases to perform tasks more efficiently than ever before, while still allowing others who may not have these skillsets access those same resources by using their own skill sets instead of waiting until someone else needs them first (in other words: everyone wins!).

In addition, this type of technology makes it easier for employees working remotely who need some sort of assistance from someone inside their company’s walls because there isn’t any geographical barrier preventing them from doing so anymore–they just need an internet connection.

Also Read: Why Is CRM Software a Game-changer When It Comes to Delivering Better Customer Experiences?

Fundamentals of Best Practices for Warehouse Operations

Warehouse management software can help you keep your warehouse running smoothly and efficiently. It’s a great tool to have when it comes to ensuring that everything is done right every time, but it’s also important to remember that there are best practices in place for how warehouses should operate.

Warehouse logistics software has been around since the beginning of time, but today, there are many different programs available from which all kinds of benefits can be gained. The most important thing about using such a system is knowing what works best for your company before spending any money on it; luckily there are many resources available online that will help guide you through this process!

Implementing best practices can streamline operations, increase efficiency and reduce costs.

Implementing best practices can streamline operations, increase efficiency and reduce costs. Best practices are proven methods that have been tested and proven to work in real-world environments, so they’re a great way for any company to save money.

However, implementing best practices isn’t just for large companies they can be implemented in small businesses as well!

Conclusion

Warehouse operations are complex, but with the right software, you can streamline and automate them. By using Warehouse Logistics Software, you’ll be able to integrate all of your warehouse activities, from receiving shipments to processing them into inventory and then sending it out on fulfillment orders. This will allow you to focus on what matters most: your customers.

Are you looking to implement Warehouse Logistics Software into your business? If yes, so, please feel free to contact us at support@aeologic.com

Also see: Our RFID Solutions

Also Read: 10 Ways to Use Artificial Intelligence to Improve Business Processes

Related Blogs:

- How AI/ML Can Change the Public Transportation Industry

- Transforming Business With Digital Technology in the Oil Palm Industry in India

- Importance of Digital Asset Management in the Retail Industry

- How AI is Transforming the Agriculture Industry

- 10 Ways to Use Artificial Intelligence to Improve Business Processes

- The Future of IoT Technology in Convenience Stores

- Building Manufacturing Resilience Through AI and ML